IOW Group

Separator Spares & Equipment, LLC is an Authorized IOW Group Distributor and Service Center. IOW Group is a leading manufacturer of separation, filtration, and fluid transfer products.

Centrifuge Filters | Oil Cleaning Centrifuges

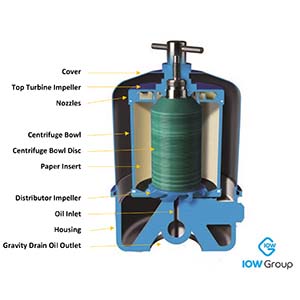

IOW Group’s centrifugal oil separators utilize bowl disc technology. Unlike conventional centrifugal spinners/separators, IOW Group centrifugal oil cleaners use bowl discs to increase the efficiency of separation, dramatically reducing the time that contaminants can stay in the oil. This provides more separation surface area. Bowl disc dramatically speeds up the precipitation of the solids from the liquid.

IOW Group centrifugal oil separators have dirt/sludge monitoring technology, which informs the operator when the separator needs servicing, saving valuable personnel time on otherwise unnecessary cleaning. The CentriClean remote monitor is Modbus or Bluetooth compatible and can be easily connected to your existing alarm systems.

Proven Reliability! Proven Impact. Proven Uptime. Proven Savings.

IOW engine oil centrifuges allow you to maximize performance, extend maintenance intervals, and reduce the total cost of ownership (TCO) for engine systems and auxiliaries. IOW centrifugal oil separators come standard with Bowl Disc Technology and External Monitoring for greater efficiency. The new standard for performance in oil separation!

Triple Screw Pumps | Mechanical Sealed or Magnetically Sealed Pumps

IOW Group provides a full range of positive displacement triple screw pumps. All IOW pumps fit within the industry-standard footprint for easy installation. There is a choice of standard mechanically sealed pumps or, for a superior seal, IOW Group has a full range of magnetically sealed pumps.

The IOW triple screw pump is compact, powerful, efficient, and reliable. The IOW pumps are designed to endure a long, problem-free operation, even in the toughest environments. IOW Group pumps are utilized in the commercial, marine, navy, power generation, and general industries.

Separator Spares & Equipment is your link to IOW Group spares, accessories, and/or complete systems.

IOW Group

Advanced Oil Filtration Solutions

What is the best centrifugal oil filter?

IOW Group has designed, patented, and manufactured the highest-performing and only self-monitoring bypass, oil filtration, spinner-type separator in the world. IOW Group has spent over 5 years redesigning the traditional centrifuge to create a new range of centrifugal oil separators. So, what makes IOW Group’s MP centrifugal oil filters so different and better?

IOW Group has designed, patented, and manufactured the highest-performing and only self-monitoring bypass, oil filtration, spinner-type separator in the world. IOW Group has spent over 5 years redesigning the traditional centrifuge to create a new range of centrifugal oil separators. So, what makes IOW Group’s MP centrifugal oil filters so different and better?

- Bowl Disc Technology – Increasing efficiency by removing even more contaminants.

- Remote Monitoring – Provides operators and systems with valuable insight into their speed, cleaning, and service requirements.

- Fully Sealed Unit – Reducing the risk of cross-contamination between cleaned and dirty oil.

- Distributor Impeller – Eliminates backpressure by drawing in contaminated oil.

Better Technology = Better Results

The combination of protection, performance, remote monitoring, and the ability to extend oil drain intervals has many turning to IOW Group as their filtration solution.

The combination of protection, performance, remote monitoring, and the ability to extend oil drain intervals has many turning to IOW Group as their filtration solution.

Better Technology:

– Bowl Disc Technology

– Modbus Remote Monitoring or Bluetooth Remote Monitoring

– Fully Sealed Centrifuge Bowl

– Eliminating Back Pressure

Better Results:

– 150% more efficient

– Reduce Engine Wear

– Reduce Maintenance

– Reduce Costs

Proven Reliability! Proven Impact. Proven Uptime. Proven Savings.

Next generation in centrifugal oil separators! IOW Group separators remove contaminants that cause damage to engines, and they also greatly extend the life of lubricating oil in both engines and gearboxes. They are the highest-performing and the only self-monitoring bypass oil filtration spinners in the world.

When replacing an old Glacier, Mann Hummel, or Spinner II oil cleaning centrifuge, choose the best centrifugal oil filter on the market — the IOW Group centrifugal oil filter.

How does a centrifugal oil filter work?

Oil is introduced into the separator bowl at engine oil pressure through holes drilled in the vertical spindle and via the accelerator channels in the bearing distributor.

Oil is introduced into the separator bowl at engine oil pressure through holes drilled in the vertical spindle and via the accelerator channels in the bearing distributor.

The bowl then fills up, and oil overflows into the top turbine, where it exits the bowl via the four speed turbine channels and then out via the nozzles. This, in turn, rotates the bowl, generating the centrifugal force required to remove the contaminants from the oil.

The contaminants migrate towards the outside of the bowl, where they are deposited on a removable oil-resistant insert. The cleaned oil migrates towards the center of the bowl, where it is expelled by the nozzles in the top turbine, thus perpetuating the cycle.

Increased Efficiency

Unlike conventional centrifugal oil spinners/separators, IOW Group centrifugal oil filters use bowl discs to increase the efficiency of separation, dramatically reducing the time that contaminants can stay in the oil.

IOW Group has improved the sealing between the dirty oil inlet and the cleaned oil outlet. This ensures that there is minimal cross-contamination between the two.

Save Valuable Man-hours

IOW Group centrifugal oil filters also have dirt/sludge monitoring technology, which informs the operator when the separator needs cleaning, saving valuable personnel time on otherwise unnecessary cleaning. The systems are Modbus or Bluetooth compatible and can be easily connected to your existing alarm systems.

Why add a centrifuge to self-cleaning lube oil filter's backflush flow?

The centrifuge removes the fine particles. By removing the very fine particles from the lube oil, you are increasing protection. Fine particles act as abrasives to the engine’s moving parts (camshaft lobe, piston rings, etc). Removing particles 35 μ or less will help lengthen the lifecycle and reduce the overall wear rate.

The centrifuge removes the fine particles. By removing the very fine particles from the lube oil, you are increasing protection. Fine particles act as abrasives to the engine’s moving parts (camshaft lobe, piston rings, etc). Removing particles 35 μ or less will help lengthen the lifecycle and reduce the overall wear rate.

The backflushing flow is directed into the centrifuge. The bowl then fills up, and oil overflows into the top turbine, where it exits via the four-speed turbine channels and then out through the nozzles. This, in turn, rotates the bowl, generating the centrifugal force required to remove the contaminants from the oil.

The gravitational force of the rotating disc stack causes the heavy particles to migrate to the wall of the centrifuge bowl. The lighter oil is directed through the outlet ports and drains back into the engine sump.

The combined use of an automatic filter and a centrifuge for lubrication oil filtration is easy to retrofit into existing engines. The overall goal of adding an IOW centrifuge to an automatic filtration system is to prevent soot and solid particles of all sizes from reaching the engine.

Is your centrifuge cleaning efficiently — or wasting money?

Upgrade to the IOW Group bypass centrifuge filter. It has superior oil filtration and separation efficiency, making it the best replacement for Spinner II Oil Cleaning Centrifuges, Glacier Centrifuge, and Mann Hummel Centrifugal Oil Cleaners.

Which engines have benefited most from IOW Group centrifuge installations?

IOW Group centrifuges deliver reliable oil protection across a wide range of engines. From Caterpillar and Perkins to MAN and Waukesha, leading reliability engineers trust the IOW Group engine oil centrifuges to extend engine life and maximize performance. The IOW Group centrifuges provide superior wear reduction and are the leader in bypass oil filtration.

IOW Group centrifuges deliver reliable oil protection across a wide range of engines. From Caterpillar and Perkins to MAN and Waukesha, leading reliability engineers trust the IOW Group engine oil centrifuges to extend engine life and maximize performance. The IOW Group centrifuges provide superior wear reduction and are the leader in bypass oil filtration.

Better Oil Cleaning Centrifuge Technology = Superior Wear Reduction

Want to learn from detailed, real-world installation case studies on these major engines? The IOW Group centrifuge filters are the top choice for major engines, including Caterpillar, INNIO Waukesha, Hyundai HiMSEN, Jenbacher, MAN Energy Solution, Progress Rail EMD, and Perkins Engines.

Brief History of IOW Group

2016 IOW Group Limited was founded in the Isle of Wight, United Kingdom.

2016 Lloyd’s Register Group Limited provided an oil spinner witness test confirming that the IOW MP200 oil centrifuge is more than 35% more efficient at removing soot and other solid contaminants over the Mann Hummel FM200-21 oil spinner.

Today, the IOW Group centrifugal filters are 40-50% more efficient than the Mann Hummel centrifuges, thanks to continued bowl and centrifuge design improvements.

2017 IOW Group LLC was founded in Houma, Louisiana, USA.

2019 Separator Spares & Equipment, LLC signed a distributor agreement and service agreement with IOW Group.

2021 IOW Group was awarded a United States Patent for its innovative oil separators, and the European Patent Register granted a patent for its innovative separators.

2022 IOW Group introduced the eQlips Q Series Backflushing Filters.

2023 IOW Group introduced the Magnaline 458 N1 and Magaline 477 N1 pumps.