Strategic Lubrication: How to Extend Oil Drain Intervals Safely

Lubricating oil is no longer merely a consumable; it is essential for the reliability and efficiency of engines and equipment. While traditional maintenance relied on schedules provided by Original Equipment Manufacturers (OEMs), the industry is shifting toward data-driven Condition-Based Monitoring (CBM). Moving to condition-based maintenance eliminates the waste of arbitrary lube oil changes while using fluid analysis to detect early warning signs of equipment failure. By moving from a reactive to a proactive strategy, organizations can reduce unplanned downtime and lower overall maintenance costs. Below are six (6) expert-level tips to optimize your lubricant drain intervals and maximize engine longevity.

Lubricating oil is no longer merely a consumable; it is essential for the reliability and efficiency of engines and equipment. While traditional maintenance relied on schedules provided by Original Equipment Manufacturers (OEMs), the industry is shifting toward data-driven Condition-Based Monitoring (CBM). Moving to condition-based maintenance eliminates the waste of arbitrary lube oil changes while using fluid analysis to detect early warning signs of equipment failure. By moving from a reactive to a proactive strategy, organizations can reduce unplanned downtime and lower overall maintenance costs. Below are six (6) expert-level tips to optimize your lubricant drain intervals and maximize engine longevity.

Get More Out of Your Lubricants with Extended Oil Drains!

#1: Align with OEM Specifications and High-Performance Formulations

The first step in any extended engine oil drain optimization program is to align your strategy with the latest OEM requirements and lubricant technology. Traditional engine oil drain intervals are often based on “worst-case” scenarios to ensure warranty compliance, but modern high-quality engine oil is designed for significantly higher stability.

Moving Beyond OEM Schedules to Extend Oil Drain Intervals

#2: Participate in Comprehensive Laboratory Testing and Analysis

Routine oil analysis is the only scientific method to determine the “Remaining Useful Life” (RUL) of a lubricant. Diesel engines are mechanical puzzles with hundreds of moving parts, and in our experience, reliability usually hinges on two factors: lubricant health and contamination control. Most field issues stem from oil degradation, specifically shear-down and oxidation, or the introduction of “engine killers” like dirt, coolant leaks, fuel dilution, and heavy soot loading. Because these threats are so prevalent, your routine test slate should be purpose-built to catch them early.

Routine oil analysis is the only scientific method to determine the “Remaining Useful Life” (RUL) of a lubricant. Diesel engines are mechanical puzzles with hundreds of moving parts, and in our experience, reliability usually hinges on two factors: lubricant health and contamination control. Most field issues stem from oil degradation, specifically shear-down and oxidation, or the introduction of “engine killers” like dirt, coolant leaks, fuel dilution, and heavy soot loading. Because these threats are so prevalent, your routine test slate should be purpose-built to catch them early.

However, when you spot a spike in wear metals that doesn’t clearly correlate with oil breakdown or a known leak, it’s time to move beyond standard chemistry. That’s where analytical ferrography comes in; it allows you to examine wear debris morphology to find a root cause that basic testing might miss. The standard lube oil analysis should evolve based on your goals. If you are pushing for extended drain intervals or auditing the ROI of a high-efficiency filtration system, incorporating Base Number (BN) and ISO Cleanliness Codes (ISO 4406) becomes essential for a complete picture.

Eliminate the Guesswork: Participate in Comprehensive Laboratory Testing and Analysis to Safely Extend Oil Drain Intervals.

#3: Implement Data Trending and Management Reports

A single oil sample is merely a snapshot; the true value of condition-based monitoring (CBM) lies in trend analysis. By running data management reports and analyzing historical results, you can establish a “trend signature” for every compartment, whether it is an engine, gearbox, or hydraulic system.

To maximize the impact of a condition-based monitoring program, you have to move away from reacting to static “red line” limits and instead focus on establishing a rigorous baseline, which generally requires three to five samples to accurately capture a machine’s unique operating signature. It is the deviation from this historical trend, not a single outlier, that serves as the true early warning sign of a developing fault. By integrating these trends into modern condition-based monitoring software, maintenance and reliability managers gain digital transparency that enables management by exception, ensuring maintenance resources are aggressively funneled toward “Red” and “Yellow” alerts while “Green” assets remain in service, optimizing both labor and machine uptime.

Beyond the Snapshot: Leverage Historical Trend Signatures to Confidently Extend Oil Drain Intervals.

#4: Identify and Monitor Key Performance Indicators (KPIs)

To safely extend lube oil drain intervals, maintenance teams must monitor specific chemical and physical markers that indicate the lubricant’s ability to continue protecting the engine or machinery. These KPIs must be evaluated holistically, as a failure in one area can accelerate degradation in another. Common KPI’s for extending drain intervals include:

-

ACID NUMBER: By measuring the amount of acid present in the used lubricant, the levels of oxidation and contamination can be indicated. If the acid number is below both the OEM and the lubricant manufacturer’s recommendations, it is safe to continue using the lubricant.

ACID NUMBER: By measuring the amount of acid present in the used lubricant, the levels of oxidation and contamination can be indicated. If the acid number is below both the OEM and the lubricant manufacturer’s recommendations, it is safe to continue using the lubricant.- BASE NUMBER (ENGINES): This test indicates the level of additives in your oil, specifically detergents and dispersants that neutralize the acidic byproducts of combustion. If the lubricant’s base number levels are above the lubricant manufacturer’s condemning limits, the oil may be safely extended.

- OXIDATION: If oxidation levels are below the condemning limit suggested by the lubricant manufacturer, this may mean the oil can still be used and the drain extended.

- NITRATION: Critical to monitor in Natural Gas Engines.

- VISCOSITY: If the lubricant’s viscosity falls within the manufacturer’s range, it may indicate the oil can be used for longer.

NOTE: These KPIs must be considered together, not individually, to determine effective extended oil drain intervals.

Look at the Whole Picture: Evaluate KPIs to Safely Extend Oil Drain Intervals.

#5: Take Decisive Action on Sample Reports

Maximizing the value of an oil analysis program requires treating every oil analysis report as a critical diagnostic asset rather than just routine paperwork. These oil analyses provide a comprehensive view of your equipment’s health, detailing everything from metallurgical wear rates and contaminant ingress to cumulative sample history and expert-driven corrective actions. Because the data represents a “snapshot in time,” the window for preventive intervention is narrow; reviewing these results immediately upon receipt is essential to identify escalating threats and execute repairs before a manageable “Yellow” alert matures into a catastrophic “Red” failure.

Turn Paperwork into Profits: Take Decisive Action on Reports to Safely Extend Oil Drain Intervals.

#6: Utilize IOW Group Centrifuges for Advanced Bypass Filtration

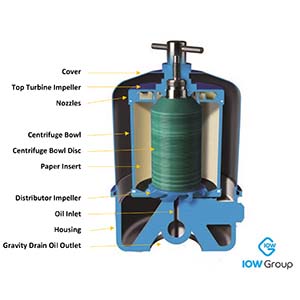

The IOW Group centrifugal bypass filters provide the oil filtration protection necessary to truly extend oil life. Standard full-flow oil filters are limited by their micron mesh size (µm). The IOW Group centrifugal bypass oil filters use centrifugal force (g-force) to separate out the solid contaminants (soot, wear metals, dirt, sludge, and other particles) from the oil. The IOW Group centrifuges function as a clarifier (clarification separation).

The IOW Group centrifugal bypass filters provide the oil filtration protection necessary to truly extend oil life. Standard full-flow oil filters are limited by their micron mesh size (µm). The IOW Group centrifugal bypass oil filters use centrifugal force (g-force) to separate out the solid contaminants (soot, wear metals, dirt, sludge, and other particles) from the oil. The IOW Group centrifuges function as a clarifier (clarification separation).

Stop Pouring Profits Down the Drain: Safely Extend Oil Drain Intervals.

Superior Technology for Maximum Contaminant Removal

-

Bowl Disc Technology: Unlike conventional oil-cleaning centrifuges, IOW Group centrifuges use internal bowl discs (conical plates). This increases the internal surface area (dwell time) and improves the separation efficiency, allowing the IOW Group centrifuges to remove significantly more small, wear-causing particles and soot.

Bowl Disc Technology: Unlike conventional oil-cleaning centrifuges, IOW Group centrifuges use internal bowl discs (conical plates). This increases the internal surface area (dwell time) and improves the separation efficiency, allowing the IOW Group centrifuges to remove significantly more small, wear-causing particles and soot.- Distributor Impeller: The distributor impeller reduces backpressure by drawing in contaminated oil. The oil enters the centrifuge at the base of the unit and, once spinning, is drawn into the centrifuge by the distributor impeller, reducing the risk of backpressure and cross-contamination, and increasing the rotor (bowl) speed.

- Remote Monitoring: IOW Group centrifuges are the only centrifugal oil cleaners on the market that offer remote monitoring. Remote monitoring provides operators with valuable insights into centrifuge speed, cleaning, and service interval requirements.

- Fully Sealed Design: To prevent cleaned oil from recontaminating incoming dirty oil, IOW units are fully sealed with O-rings, ensuring 100% integrity of the cleaning circuit.

IOW Group Centrifugal Filters Provide the Protection Needed to Extend Oil Drain Intervals!

In the long run, the decision to extend oil drain intervals is about more than just reducing maintenance costs; it’s about maximizing your engine life and engine efficiency. By moving away from arbitrary schedules and embracing data-driven oil analysis, you can monitor critical components and adapt to specific operating conditions, ensuring they remain protected. Implementing advanced bypass filtration not only helps maintain longer service intervals but also improves fuel economy by keeping the lubricant clean and friction low. Do not wait for a standard service interval to address your equipment’s needs, upgrade your oil filtration strategy today, and make every oil change a strategic investment in long-term reliability.

Call us today to learn about the best engine oil centrifuge! While the centrifugal oil filters may look similar, the IOW Group’s centrifugal oil cleaners technology is patent-protected. Not only is the IOW Group’s offline filtration system technology one of a kind, but the IOW centrifugal oil filters are 150% more efficient than Mann Hummel centrifugal oil cleaners, Glacier centrifuges, Spinner II oil cleaning centrifuges, Mircospin centrifuges, or any current option.

Leading engine brands trust these centrifugal oil filters, including Caterpillar, INNIO Waukesha, Hyundai HiMSEN, Jenbacher, MAN Energy Solution, Progress Rail EMD, and Perkins Engines. BUT, not all centrifugal filters are created equal. IOW Group has designed, patented, and manufactured the world’s highest-performing and only self-monitoring bypass oil filtration spinner-type separator. For more information, visit What is a Bypass Oil Centrifuge?

IOW Group vs. Spinner II Oil Cleaning Centrifuges

Upgrade Your Oil Filtration, Upgrade Your Uptime!

Leverage IOW Group Centrifuges to Extend Oil Drain Intervals by Up to 50%.