Industrial Oil Filtration

What is Oil Filtration?

Oil filtration is the critical process of removing undissolved solid contaminants and moisture from a lubricant or fluid stream. This is achieved by passing the fluid through a porous medium (mechanical filtration) or by applying external forces, such as centrifugal separation (centrifugal force) or magnetic attraction. In the context of industrial reliability, oil filtration is not merely a maintenance task; it is the primary defense mechanism for the longevity of machinery. By maintaining strict ISO 4406 cleanliness levels, oil filtration prevents the “chain reaction of wear,” where small particles create more particles through abrasion, eventually leading to catastrophic component failure.

Effective oil filtration relies on advanced filtration systems designed to protect lubricating oil, hydraulic oil, and diesel fuel by removing small particles and other contaminants that compromise equipment performance. Comprehensive oil purification begins with evaluating an oil sample to determine contamination levels, as even new oil can contain harmful debris introduced during handling and storage. High-efficiency oil filters, including continuous flow filter solutions, help maintain cleanliness without interrupting system operation, while offline filtration systems help ensure optimal cleanliness levels. Together, these technologies support proactive maintenance strategies and are reflected in our featured products, which are engineered to extend oil life, reduce wear, and improve overall system reliability.

Why Oil Filtration is the Foundation of Reliability?

Effective oil filtration targets the “invisible killers”, small particles in the 4µm to 14µm range. While these are invisible to the naked eye, they are large enough to bridge the lubricant film between moving parts, causing:

-

- Component Wear: Solid contaminants in oil act as abrasive agents, much like sandpaper, accelerating wear on critical components such as pumps, valves, bearings, and cylinders. As these particles circulate through the system, they grind against metal surfaces, causing abrasive wear and increased clearances; at higher velocities, they can pit surfaces and remove material through erosive wear. Over time, particles that become embedded or trapped in load zones subject components to repeated stress, leading to fatigue wear, surface cracking, and ultimately premature equipment failure.

- Reduced Oil Life: Contaminants accelerate oxidation, leading to premature oil degradation and frequent changes.

- Unscheduled Downtime: A single pump failure in a high-output production line can cost thousands of dollars per hour.

- Energy Inefficiency: Varnish and sludge buildup increase friction and heat, forcing systems to work harder.

The Cleaner the Oil, the Longer the Life

An effective oil filtration system is essential to control these wear mechanisms and protect system reliability. Contamination is the leading cause of hydraulic and lubrication system failure. Research indicates that up to 80% of all system failures are directly related to fluid cleanliness. By implementing a strategic oil filtration program, including kidney-loop systems and high Beta-ratio filters, industries can extend the Mean Time Between Failures (MTBF) of their assets.

Types of Oil Contaminants

To effectively manage oil filtration, it is essential to first understand the sources of contamination. Oil contaminants generally fall into three (3) primary categories: solid particles, water contamination, and chemical contaminants, commonly referred to as varnish. Each type poses distinct risks to lubricant performance and equipment reliability, and each requires a targeted oil filtration strategy to control and remove it.

To effectively manage oil filtration, it is essential to first understand the sources of contamination. Oil contaminants generally fall into three (3) primary categories: solid particles, water contamination, and chemical contaminants, commonly referred to as varnish. Each type poses distinct risks to lubricant performance and equipment reliability, and each requires a targeted oil filtration strategy to control and remove it.

Solid Particulates

Solid particulate contamination includes external sources (environmental/operational ingress), internal sources (wear and degradation), or industrial/process contaminants. External sources include, but are not limited to, dirt, sand, grit, and dust from the surrounding air (silica, aluminum, calcium); soot from incomplete combustion (especially in diesel engines); paint flakes from painted machine surfaces; rust and corrosion byproducts; and others. Internal sources include, but are not limited to, wear debris from metal particles from components such as bearings, gears, piston rings, and seals; rust and corrosion byproducts (iron oxides and other corrosion particles); and others.

Occasionally, industrial and process contaminants are present in the oil, including fibers and cellulose (from paper, filters, or other materials); carbon and coke fines (from industrial processes); and others. Solid contaminated particles are measured in microns (µm). Industrial wear is often caused by particles smaller than 40µm, which are invisible to the naked eye.

Water Contamination

Water exists in oil in three states: dissolved water (individual molecules), emulsified water (tiny, stable droplets forming a haze), and free water (visible, separated water). Each type of water contamination causes severe issues such as accelerated oxidation, corrosion, and reduced lubrication film, drastically reducing bearing life. Sources of water contamination include condensation, leaks, or improper handling. Water contamination reduces lubrication, and water destroys the oil film, leading to bearing failure. Water promotes rust (corrosion), acidic byproducts, and speeds up oil breakdown (accelerated oxidation). Water contamination will consume or deactivate oil additives.

Chemical Contaminants (Varnish)

Varnish is a tenacious, surface-adherent film that is hard to remove and can cause sticking. Varnish is not a contaminant itself but a byproduct of oil breaking down due to heat, oxygen, and stress, creating insoluble deposits. Varnish is a thin, insoluble film that forms on internal machine parts. The “sticky” deposits can clog valves and filters, and clog passages by trapping fine particles and restricting flow.

-

- Oxidation: Heat and oxygen break oil molecules, forming acids and high-molecular-weight polymers (varnish precursors) that eventually precipitate out as deposits.

- Thermal Stress: Localized overheating rapidly degrades oil, forming sticky, brown films that harden into lacquer.

- Additive Breakdown: Consumed additives and their degradation products (carboxylic acids, metal soaps) contribute to deposit formation.

Common Oil Contaminants and Damage Mechanisms

| Contaminant | Type | Damage Mechanism | Recommended Filtration |

| Silica/Dirt | Solid | Abrasive wear; destroys seals and valves | Barrier / Offline |

| Metal Fines | Solid | Catalytic oxidation; accelerates oil aging | Centrifugal / Magnetic |

| Dissolved Water | Moisture | Hydrogen embrittlement; additive depletion | Vacuum Dehydration |

| Free Water | Moisture | Rust; film strength loss; bearing failure | Centrifugal / Coalescing |

| Varnish | Chemical | Sticky valves; restricted flow; heat buildup | Adsorption / Depth |

How Industrial Oil Filtration Works?

An effective oil filtration system serves as the primary defense mechanism for industrial machinery, removing solid particulates, moisture, and oxidation byproducts from hydraulic, lubricating, and process oils. The process of oil filtration typically operates through a dedicated “kidney loop” or “in-line” system, in which a high-pressure pump draws contaminated fluid from a reservoir and forces it through specialized oil filter media or separators.

An effective oil filtration system serves as the primary defense mechanism for industrial machinery, removing solid particulates, moisture, and oxidation byproducts from hydraulic, lubricating, and process oils. The process of oil filtration typically operates through a dedicated “kidney loop” or “in-line” system, in which a high-pressure pump draws contaminated fluid from a reservoir and forces it through specialized oil filter media or separators.

To achieve critical ISO 4406 cleanliness targets, such as 16/14/11 for hydraulics and 18/16/13 for gearboxes, the oil filtration system utilizes three distinct mechanics of capture: (1) Direct Interception, where large particles are physically sieved on the media surface; (2) Inertial Impaction, which utilizes high-velocity flow to drive debris deep into a dense fiber matrix; and (3) Adsorption, where molecular attraction pulls sub-micron varnish and soft contaminants onto the media fibers. By integrating advanced moisture removal technologies like vacuum dehydrators or coalescers into this flow, an optimized oil filtration strategy ensures that only purified, high-purity oil returns to the machine, effectively halting the “chain reaction of wear” and extending the mean time between failures (MTBF).

Common Oil Filtration Types

The establishment of target cleanliness levels is a strategic decision that balances the cost of oil filtration against the required reliability and the machinery’s lifespan. Different components have vastly different tolerances for contamination, and “one-size-fits-all” filtration strategies often lead to either premature failure or excessive maintenance spending.

There is no single oil filtration solution that fits every application. The best oil filtration approach depends on multiple factors, including the fluid type, system design, operating environment, contamination sources, required flow rate, and the target oil cleanliness level. Equipment duty cycle, temperature, and pressure conditions also play a critical role in determining the most effective oil filtration strategy. By understanding these variables, industrial and marine operators can select the appropriate combination of oil filtration technologies, such as full-flow filtration, offline filtration, and centrifugal oil filtration, to achieve reliable contamination control, extend oil life, and protect critical machinery.

There is no single oil filtration solution that fits every application. The best oil filtration approach depends on multiple factors, including the fluid type, system design, operating environment, contamination sources, required flow rate, and the target oil cleanliness level. Equipment duty cycle, temperature, and pressure conditions also play a critical role in determining the most effective oil filtration strategy. By understanding these variables, industrial and marine operators can select the appropriate combination of oil filtration technologies, such as full-flow filtration, offline filtration, and centrifugal oil filtration, to achieve reliable contamination control, extend oil life, and protect critical machinery.

Full-Flow Filtration (In-line Filtration)

Full-flow filters are designed to filter 100% of the oil as it circulates through the main system, protecting components directly, but they often cannot get the oil as clean as offline systems. These oil filters are installed in the main pressure line. Every drop of oil passes through the filter before reaching the components. While effective for immediate protection, a full-flow filtration system is limited by the pressure drop it can tolerate.

Offline Filtration (Kidney Loop System)

An offline filtration system is a dedicated system that operates independently of the main inline filtration system. It draws oil from the reservoir, cleans it, and returns it. Offline filtration only filters a small portion of the oil at a time (a side stream). Still, it does so continuously, often achieving extremely fine filtration and returning clean oil to the sump. This allows for ultra-fine filtration without affecting system pressure.

An offline filtration system is a dedicated system that operates independently of the main inline filtration system. It draws oil from the reservoir, cleans it, and returns it. Offline filtration only filters a small portion of the oil at a time (a side stream). Still, it does so continuously, often achieving extremely fine filtration and returning clean oil to the sump. This allows for ultra-fine filtration without affecting system pressure.

Centrifugal Filtration

Centrifugal filtration uses rapid spinning to separate denser solids and water from lighter oil using centrifugal force, often in oil purification or clarification separation processes.

Technical Comparison of Oil Filtration Methods

Centrifugal Separation

Centrifugal separation is a highly effective oil filtration method that uses high-speed rotation to generate intense G-forces (centrifugal force) within the separator. As the oil spins, heavier contaminants, such as free water and solid particles, are forced outward and separated from the lighter oil phase. This process enables continuous oil purification and clarification without restricting flow.

Centrifugal separation is a highly effective oil filtration method that uses high-speed rotation to generate intense G-forces (centrifugal force) within the separator. As the oil spins, heavier contaminants, such as free water and solid particles, are forced outward and separated from the lighter oil phase. This process enables continuous oil purification and clarification without restricting flow.

Centrifugal separators are ideal for industrial applications that require high-volume water removal, handling heavy solids, and continuous operation in demanding industrial and marine environments. Centrifugal oil filtration operates without disposable filter elements, eliminating clogging, reducing pressure drop, and significantly lowering maintenance costs and operating costs compared to traditional oil filtration methods.

Barrier Filtration (Media Filtration)

Barrier filtration, or media-based, uses physical filter media, such as cellulose, synthetic fibers, or stainless steel mesh, to mechanically capture contaminants as oil flows through the filter element. Particles larger than the media’s pore size are retained, delivering consistent and measurable contaminant control across a wide range of oil filtration applications.

Barrier filtration, or media-based, uses physical filter media, such as cellulose, synthetic fibers, or stainless steel mesh, to mechanically capture contaminants as oil flows through the filter element. Particles larger than the media’s pore size are retained, delivering consistent and measurable contaminant control across a wide range of oil filtration applications.

Oil filtration systems requiring fine particulate removal, typically down to 1 micron (1 µm), where achieving specific cleanliness targets is critical for component protection and system reliability. Barrier filtration is commonly used in full-flow and offline oil filtration systems and is often combined with centrifugal oil filtration to provide comprehensive contamination control.

What is the Beta Ratio (βx)?

In barrier filtration, the Beta Ratio defines efficiency. A rating of β10 = 1000 means only 1 out of 1000 particles (10 microns or larger) passes through the media (99.9% efficiency). For critical hydraulic circuits, we recommend filters with a Beta Ratio of 200 or higher.

Vacuum Dehydration

Vacuum dehydration is a high-performance, advanced oil purification process designed to remove free, emulsified, and dissolved water, as well as entrained air and gases, from lubricating and insulating oils. By exposing the oil to a controlled vacuum environment, the process significantly reduces the boiling point of water. This allows moisture to be vaporized and removed at low operating temperatures, typically around 130°F (54°C). This low-temperature method preserves the oil’s chemical properties and additive integrity while dramatically increasing oil dryness and oxidative stability.

Vacuum dehydration is a high-performance, advanced oil purification process designed to remove free, emulsified, and dissolved water, as well as entrained air and gases, from lubricating and insulating oils. By exposing the oil to a controlled vacuum environment, the process significantly reduces the boiling point of water. This allows moisture to be vaporized and removed at low operating temperatures, typically around 130°F (54°C). This low-temperature method preserves the oil’s chemical properties and additive integrity while dramatically increasing oil dryness and oxidative stability.

This process is best suited for oil purification applications where removing dissolved water is critical. It is particularly essential for turbine oils and transformer oils, where moisture contamination can severely degrade dielectric strength, accelerate oil oxidation, and compromise equipment reliability.

Technical Comparison of Oil Filtration Methods

To select the appropriate technology, one must compare removal efficiencies across various contaminant phases.

| Performance Metric | Centrifugal Separation | Barrier (Media) Filtration | Vacuum Dehydration |

| Primary Target | Free Water & Large Solids | Fine Particulates (microns) | Dissolved Water & Gases |

| Removal Efficiency | 99% of free water/solids | Rated by Beta Ratio (βx) | Down to 10 PPM Water |

| Solid Handling | High (self-cleaning units) | Low (filters clog frequently) | Minimal (requires prefilter) |

| Dissolved Water | No | No | Yes (Best in Class) |

| Varnish Removal | Moderate | Only with specialized media | Limited |

| Operational Cost | Low (no consumables) | High (filter replacements) | Moderate (power intensive) |

Industry Standards: Understanding ISO 4406

In industrial maintenance and lubrication management, a widely accepted principle holds true that “Equipment cleanliness is directly tied to operational reliability, asset longevity, and overall profitability.” For reliability engineers and maintenance professionals, “clean” is not a subjective observation made by looking at an oil sight glass. Instead, cleanliness is defined by a rigorous, data-driven metric known as the ISO 4406 Cleanliness Code.

What is the ISO 4406 Cleanliness Code?

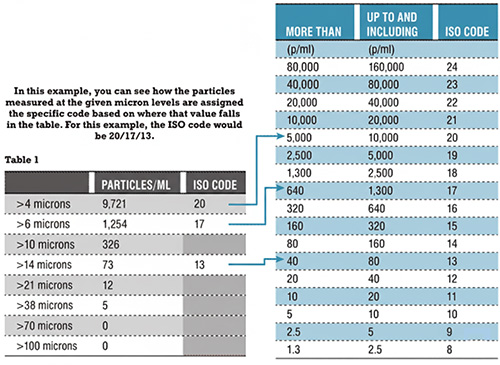

The ISO 4406:2021 standard is the global benchmark for representing the level of particulate contamination in a fluid. Because counting every single particle in a lubricant is impossible and unnecessary, the standard uses a simplified coding system to represent the distribution of particles across three critical size ranges.

Expert Tip: Never rely on a visual inspection of oil; 90% of damaging contaminants are below the limit of human visibility (40µm).

To standardize the measurement of particulate contamination in these fluids, the International Organization for Standardization (ISO) established the ISO 4406 standard. This code provides a clear, straightforward method for reporting the number of solid contaminant particles in a fluid oil sample.

Understanding the ISO 4406 Code Format

Understanding the ISO 4406 Code Format

The ISO 4406 cleanliness code is expressed as a series of three numbers, such as 18/16/13. Each number corresponds to the quantity of particles of a specific size range per milliliter of the fluid. The three size ranges measured are:

-

- 1st Number (Particles > 4µm): Represents silting particles. These fit into tight clearances (1-5 microns) in servo valves and high-pressure pumps, causing stiction and sluggish response.

- 2nd Number (Particles >6µm): Represents abrasive wear particles. These grind away surfaces in bearings and gear meshes.

- 3rd Number (Particles >14µm): Represents larger particles that cause catastrophic failure, blocking orifices, or causing rapid erosive wear.

The code is determined by a logarithmic scale, where each increasing code number represents a doubling of the particle count range. This system allows for a concise representation of a wide range of contamination levels. Adhering to ISO 4406 standards isn’t just about passing audits. It’s about extending the mean time between failures (MTBF) of critical assets. To learn more about the ISO cleanliness code, visit Noria’s What is the ISO Cleanliness Code?

The Logarithmic Nature: Why One Number Changes Everything

One of the most common mistakes in interpreting ISO 4406 is treating the numbers as a linear scale. In reality, the scale is logarithmic. Each increase in a code number signifies a doubling of the contamination level. For example, an ISO code of 18 represents a range of 1,300 to 2,500 particles per ml. If that number jumps to 19, the range increases to 2,500 to 5,000 particles per ml.

The Significance of the Micron (µm)

To put these sizes into perspective, a human hair is roughly 70µm to 100µm in diameter. The naked eye can generally only see particles larger than 40µm. This means the ISO 4406 code is tracking “invisible killers”, contaminants that are small enough to enter the tightest clearances of a machine but hard enough to cause catastrophic abrasive wear.

Cleaner Oil = Longer Equipment Life

How to Choose an Oil Filtration System?

If you are searching for an “oil filtration system,” you are likely facing a critical decision: how to choose the right one for your application, whether you are maintaining hydraulic machinery, protecting turbines, or extending engine life. Selecting the right oil filtration system has a direct impact on performance, reliability, and cost. The first step is assessing your specific application. Not all oils or systems are the same. Start by identifying the type of oil you are using, whether it is hydraulic fluid, engine oil, turbine oil, or gear oil. The viscosity and chemical makeup of the oil can influence which types of oil filtration systems are compatible.

If you are searching for an “oil filtration system,” you are likely facing a critical decision: how to choose the right one for your application, whether you are maintaining hydraulic machinery, protecting turbines, or extending engine life. Selecting the right oil filtration system has a direct impact on performance, reliability, and cost. The first step is assessing your specific application. Not all oils or systems are the same. Start by identifying the type of oil you are using, whether it is hydraulic fluid, engine oil, turbine oil, or gear oil. The viscosity and chemical makeup of the oil can influence which types of oil filtration systems are compatible.

Next, consider your flow rate requirements. How much oil needs to be processed per minute (GPM) or hour (GPH)? This affects the size, pressure rating, and filter media you’ll need. Just as important is identifying the type of contamination you are facing. Solid particles, such as soot, dirt, sludge, carbon, and metal shavings, are best captured by centrifugal filtration. Water contamination, common in compressors and gearboxes, is more effectively handled by coalescing filters or vacuum dehydration systems. For degraded oil byproducts such as varnish and sludge, membrane or depth filtration is usually required.

Another critical piece in the decision-making process is understanding ISO cleanliness levels (codes). These codes, defined by ISO 4406, measure the level of particle contamination in oil. For example, a cleanliness code of 18/16/13 refers to the number of particles larger than 4 µm, 6 µm, and 14 µm (microns), respectively. OEMs often specify target ISO levels for warranties and performance standards, so knowing your current contamination level and what you need to achieve helps you define your oil filtration goals more precisely.

Cost is always a concern, but it is essential to look beyond the upfront price tag. A comprehensive cost comparison should include installation, maintenance, energy use, and oil filter replacement intervals. Systems with higher initial costs might offer better long-term value by reducing oil changes, extending equipment life, and minimizing downtime. Think in terms of total cost of ownership (TCO) over several years rather than just the purchase price.

Choosing the right oil filtration system isn’t just about specifications. It is about fit, performance, and long-term reliability. A tailored solution aligned with your specific needs will deliver better protection, lower costs, and fewer headaches in the long run. With a broad range of cost-effective oil filtration systems, Separator Spares & Equipment offers oil filtration solutions to meet your industrial fluid filtration needs.

Reduce maintenance costs, improve equipment reliability, and keep your equipment moving!

Industrial Applications: Sector-Specific Oil Filtration Strategies

Marine and Offshore Industry

In maritime environments, oil filtration must handle high volumes of water ingress and heavy vibration. Centrifugal purifiers are the standard for cleaning main engine lube oil and fuel, ensuring that large-bore engines can operate on heavy fuel oil (HFO) or marine diesel (MDO) without catastrophic liner wear.

To learn more about diesel fuel filtration, visit Diesel Fuel Filtration Solutions for Marine, Power Generation, and Industrial Engines.

To learn more about engine oil filtration systems, visit Engine Oil Filtration System: The Ultimate Guide to Protecting Your Engine, Maximizing Uptime.

To learn more about fuel oil filtration systems, visit The Best Fuel Oil Filtration Systems!

To learn more about hydraulic oil filtration systems, visit Hydraulic Oil Filtration Systems & Water Removal Solutions.

To learn more about lube oil filtration systems, visit The Best Lube Oil Treatment Systems!

Mining and Heavy Construction

Equipment in the mining and heavy construction industries is exposed to extreme atmospheric dust. Modern oil filters are engineered to capture small particles and other contaminants that accelerate wear in hydraulic and lubrication systems. High-performance offline filtration carts (kidney loop filter carts, portable oil filter carts) are used to “polish” hydraulic oil to 16/14/11 levels, extending hydraulic cylinder life by up to 4x.

To learn more about hydraulic oil polishing, visit Hydraulic Oil Filtration Systems & Water Removal Solutions.

To learn more about lube oil filtration systems, visit The Best Lube Oil Treatment Systems!

Power Generation (Turbines & Transformers)

Turbine oils are highly susceptible to varnish and dissolved water. In this sector, vacuum dehydration is combined with specialized varnish removal units to maintain dielectric strength and prevent “servo-valve sticking,” which can cause power grid instability.

To learn more about fuel oil filtration systems, visit The Best Fuel Oil Filtration Systems!

To learn more about hydraulic oil polishing, visit Hydraulic Oil Filtration Systems & Water Removal Solutions.

To learn more about lube oil filtration systems, visit The Best Lube Oil Treatment Systems!

To learn more about upgrading your oil conditioning system, visit Why Upgrading to the TURBO-TOC Series 2 is an Unstoppable Advantage!

To learn more about turbine oil filtration systems, visit Turbine Oil Filtration: The Key to Reliable Power and Lower Costs.

To learn more about varnish removal, visit Varnish Removal System: The Guide to Turbine Oil Filtration.

Separator Spares & Equipment is committed to providing cost-effective oil filtration systems that will positively impact your business. ISO oil cleanliness levels and contamination control are vital to a proactive maintenance strategy. We can assist with oil purification products, solutions, and expertise. We offer a broad range of oil filtration products for industrial fluids designed to remove particles, water, varnish, and other contaminants. Our cost-effective oil filter systems will lower maintenance costs (lowering the total cost of ownership), increase reliability, and reduce energy consumption.

Separator Spares & Equipment is committed to providing cost-effective oil filtration systems that will positively impact your business. ISO oil cleanliness levels and contamination control are vital to a proactive maintenance strategy. We can assist with oil purification products, solutions, and expertise. We offer a broad range of oil filtration products for industrial fluids designed to remove particles, water, varnish, and other contaminants. Our cost-effective oil filter systems will lower maintenance costs (lowering the total cost of ownership), increase reliability, and reduce energy consumption.

Do you need any spare oil filter parts? Separator Spares & Equipment specializes in genuine and compatible oil filter spare parts, including elements, housings, and accessories for every application. We are committed to providing several types of reliable filtration solutions that reduce maintenance and minimize downtime.

Oil Filtration Machine | Solutions, Service, and Expertise