H2O BOSS Oily Water Separator

Separator Spares & Equipment, LLC is an Authorized Service Center and Distributor for H2O BOSS Oily Water Separators. In 2021, H2O, LLC acquired the assets of BOSS Separators, oily water separators designed for the maritime industry. H2O manufactures a complete line of oily water separators, marine sanitation devices, and reverse osmosis desalination systems.

BOSS Separator

The H2O BOSS oily water separator (OWS) is a marine bilge treatment system specifically engineered to meet the stringent international standards set by IMO Resolution MEPC.107(49). All BOSS oily water separators are IMO MEPC.107(49) certified and have USCG, ABS, BV, and MED Certificates of Approval.

BOSS Separator Design

The H2O BOSS 107 oily water separation system includes the following basic components: BOSS Oil Water Separator, Post Separator Polisher, and Oil Content Monitor (OCM). The BOSS oily water separator is designed and certified to remove oils, grease, and other hydrocarbons from water in accordance with IMO standards as defined in MEPC 107(49).

The first stage of the H2O BOSS oily water separator system removes marine residual fuel oil in accordance with ISO 8217, type RMG 35 (density at 15 °C not less than 980 kg/m3), and marine distillate fuel oil in accordance with ISO 8217, type DMA (density at 15 °C not less than 830 kg/m3). As specified in Resolution MEPC.107(49), these fluids are referred to as Fluid A and Fluid B, respectively.

The second stage of the H2O BOSS oily water separator system removes emulsified oil, including oil-in-water emulsions, utilizing organoclay-based bulk media. This stage is specifically engineered to meet the stringent testing requirements for Test Fluid C, a stable emulsion of oil, water, and surfactants, as defined in Part 1.2 of the Annex to Resolution MEPC.107(49). Fine particulate matter is removed through specialized filtration stages.

Water discharge quality is continuously monitored by a 15 ppm bilge alarm (oil content monitor, OCM). When operated according to specifications, the H2O BOSS bilge system is designed to consistently outperform the discharge limits set by IMO Resolution MEPC.107(49).

BOSS Oily Water Separator

Bilge Water Treatment

Features & Advantages

– IMO MEPC.107(49) certified bilge monitor

– Low capital cost

– Low maintenance

– Simple to install and operate

– Small footprint

– Works simply, and simply works

Optional Equipment

– Automatic Backwash

– Heater Option

– High Lift Option – Designed for situations requiring higher suction lift and can pull up to 16 feet (5 meters) of negative head.

– MOV Option – If the inlet has a positive head, then a MOV is required for the oil discharge.

– Rig Unit Option – Includes a stainless steel panel, a motorized ball valve on the oil discharge instead of a check valve, armored cable, sample ports, and other minor upgraded features.

-Skid or Drip Pan Mounted

– System suitable for Zone 2 (Class I, Div II) or Zone 1 (Class I, Div I)

Models and Specifications

| Model Number | Capacity m3/h (GPM) | Depth* (in) | Width* (in) | Height* (in) | Weight* (lbs) |

| BOSS 2.2T/107 | 0.5 (2.2) | 42" | 27" | 56" | 480 |

| BOSS 2.2T/107Y | 0.5 (2.2) | 29.25" | 32.64" | 41.5" | 354 |

| BOSS 5T/107 | 1.1 (5) | 48" | 32" | 58" | 775 |

| BOSS 11T/107 | 2.5 (11) | 58" | 37" | 77" | 1275 |

| BOSS 25T/107 | 5.7 (25) | 78" | 47" | 80" | 2475 |

| BOSS 45T/107 | 10.2 (45) | 101" | 56" | 85" | 3875 |

* Approximate dimensions and weights

Components of standard H2O BOSS Oily Water Separator

The H2O BOSS oily water separator is designed and certified to remove oils, grease, and other hydrocarbons from water in accordance with IMO standards as defined in MEPC 107 (49). Additional features are available to address specific situations or improve system performance to exceed MEPC standards. Water quality is monitored with a certified oil content monitor.

The system you have may or may not have some of the following components, depending on how the system was ordered initially or modified since the system was installed. If operated properly, the H2O BOSS bilge water system will meet and exceed all the requirements of MEPC 107 (49).

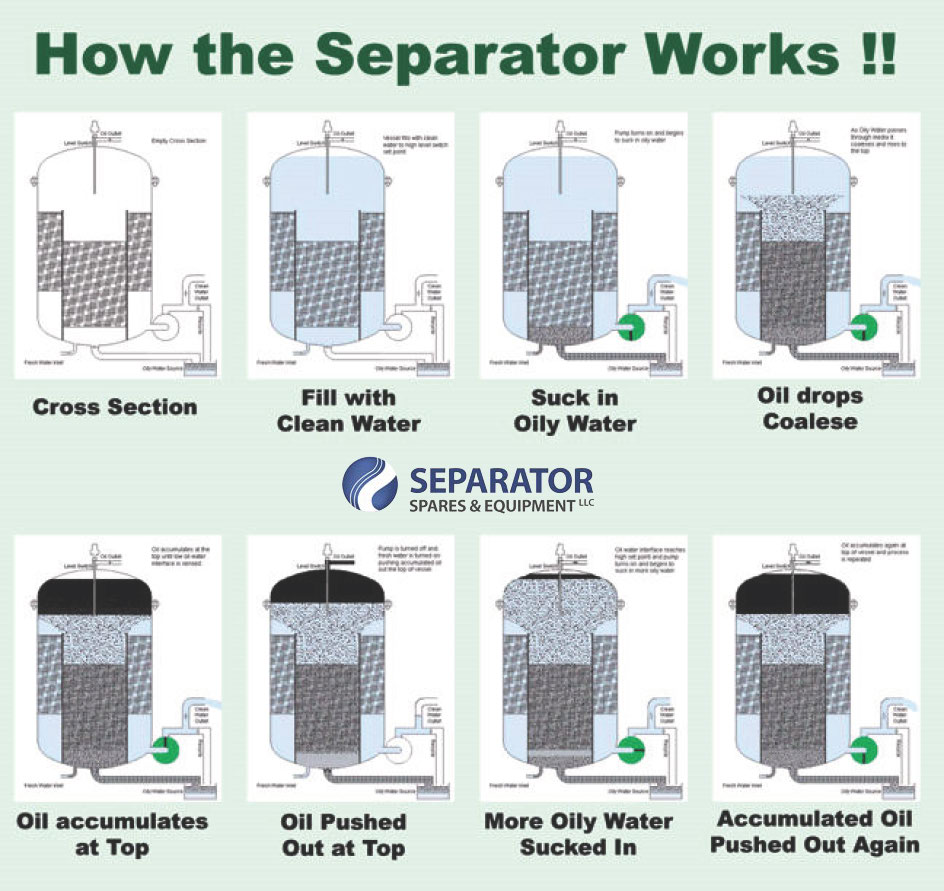

How does H2O BOSS oily water separator work?

The H2O BOSS oily water separator is first filled with clean water. A centrifugal pump (P-101) pulls oily water from a sump, bilge, or holding tank into the bottom center section of the coalescing separator (S-101) through a pre-filter Y strainer (F-101). The separator has an inner and outer section. As the oily water enters the inner center section, its velocity slows down, and it rises up through the center section of the separator. As it rises, it passes through an oleophilic media (polypropylene). The media facilitates the separation of oil from water by providing a surface area that attracts oil droplets and holds them until they coalesce into larger droplets, which then rise to the surface of the water in the separator.

The oil droplets rise to the top of the separator, collect, and then displace the water, forcing the water level in the separator downward. Any air or gas vapor that enters the separator will rise rapidly to the top, where it also collects with the oil. Air or vapor that collects in the separator will be discharged with the oil.

The water then spills over the inner weir and flows down through another layer of media to the bottom of the separator. Passing through the second stage of coalescing media further removes residual oil droplets, which rise to the top of the separator. Separated water exits the separator out the bottom of the outer section through the pump (P-101), then is pumped under pressure through the flow meter (FI-101), the post-separator bag filter (F-104), the post-filter media, and finally, the flow control valve (V-003). The polisher is equipped with manual backwash valves (V-106 & V-107) to remove accumulated fines from the polisher media. The backwash discharge is usually directed back to the bilge or holding tank.

A conductance-level sensor (LS-101) located at the top of the separator detects the water/oil level. When the water is displaced by the collected oil-air-gas to a predetermined low water/oil interface level, the system switches from normal separating, called “PUMP & WATER DISCHARGE” mode, to “FILL & OIL DISCHARGE” mode (see the lights on the panel. The pump (P-101) turns off, the discharge valve (SV-102 and or the recycle valve (SV-103) close, the water makeup valve (SV-101) and the oil discharge motor-operated ball valve (MOV-101, if equipped) open. Makeup water is allowed in, pressurizing the separator and raising the water level. The oil-air-gas is pushed out of the separator through the oil-out valve. Once the water reaches the high level, the level sensor switch shuts the makeup water and oil out valves. Normal “PUMP & WATER DISCHARGE” mode resumes.

The operation of the discharge and recycle valves is directly controlled by the oil content monitor (OCM). Various models and types of OCM units are available. If the water flow at the discharge valve contains less than 15 ppm of oil on a standard system (5 ppm on some units), the water may be discharged overboard or to another appropriate collection receptacle or drainage system. If it exceeds the preset oil content ppm level, it is directed through the recycle valve back to the oily water source.

If you still have questions, Separator Spares & Equipment offers a full range of H2O BOSS oily water separator services. Our full-time service department provides the best-in-class oily water separator service. To learn more, visit our Oily Water Separator Service and Solutions webpage.

How does an oil content monitor function?

The H2O BOSS oily water separators include an oil content monitor (OCM) that has been certified to meet the MEPC 107(49) regulations. It is sometimes called a Total Petroleum Hydrocarbon (TPH) monitor or bilge alarm.

The OCM monitor has the ability to automatically return non-conforming discharge water back to the sump or bilge. The recycle solenoid valve (SV-103) and the oil-in-water monitor (OCM) control the recycle action. The OCM unit is a 15 PPM oil content alarm monitor that has been tested and approved in accordance with IMO Resolution MEPC.107 (49). The OCM monitor continually samples the process stream and detects the oil concentration. It is designed to react quickly to any changes in the oil content.

The H2O BOSS oily water separator can be ordered with any 107(49) certified monitor. The standard OCM comes with a 15 PPM limit. The OCM allows the limit to be set in a range from 1 PPM to 15 PPM, but it cannot be set above 15 PPM. In some cases, a 5 PPM discharge is required. If this is the case, it can be handled by either setting the standard OCM to 5 PPM or by ordering a special 5 PPM version of the OCM that cannot be set above 5 PPM.

Troubleshooting & Spare Parts for H2O BOSS Separators

Separator Spares & Equipment, LLC offers a full range of services for H2O BOSS oily water separators and oil content monitors. We are committed to keeping your current BOSS oily water separator environmentally compliant with US Coast Guard and IMO MEPC 107(49) requirements. We can provide scheduled maintenance services to assist the operator in essential maintenance functions.

Separator Spares & Equipment, LLC offers a full range of services for H2O BOSS oily water separators and oil content monitors. We are committed to keeping your current BOSS oily water separator environmentally compliant with US Coast Guard and IMO MEPC 107(49) requirements. We can provide scheduled maintenance services to assist the operator in essential maintenance functions.

With our experience in oily water separators, Separator Spares & Equipment can provide the following services:

– H2O BOSS Factory-Trained Service Technicians

– Annual inspection, maintenance, repair, and service your BOSS Separators

– Oil content monitor calibration verification

– On-site training for vessel personnel

– Genuine H2O BOSS spare parts

– Replacement oil content monitors

– New IMO MEPC 107(49) certified oily water separators

To learn more, visit our Oil Water Separator Service and Solutions webpage.