MME Group

Separator Spares & Equipment, LLC is an Authorized MME Group Distributor, supporting customers across the marine, offshore, and industrial sectors. Materiaal Metingen Europe BV, also known as MME Group, is a market leader in cathodic protection, impressed current cathodic protection (ICCP), antifouling systems, sacrificial anodes (aluminum anodes, zinc anodes), and boarding equipment. MME Group delivers proven technologies that address corrosion, biofouling, and safe access challenges in demanding operating environments.

Materiaal Metingen Europe BV | MME Group

Materiaal Metingen Europe BV, also known as MME Group, is a market leader in marine and offshore asset protection and boarding equipment. Its core technologies include impressed current cathodic protection (ICCP), sacrificial anode systems, impressed current anti-fouling (ICAF/MGPS), and Harbinger boarding equipment. All MME Group products and solutions are developed with a strong focus on durability, performance, and lifecycle value.

MME Group solutions are deployed across a wide range of industries, including shipping and shipbuilding, offshore oil and gas, offshore wind and renewable energy, ports and terminals, and heavy industrial infrastructure. MME Group systems are used worldwide to protect hulls, offshore structures, seawater systems, and critical equipment from corrosion and marine growth, while also enabling the safe transfer of crew and passengers. Key application areas include hull and structure corrosion protection, seawater intake biofouling prevention, accommodation ladders and gangways for safe access, and inspection and testing services that support long-term asset integrity.

MME Group products and systems are engineered in accordance with international standards and classification society requirements, including ISO, IMO, and classification society approvals, where applicable.

- Cathodic Protection – Impressed Current Cathodic Protection (ICCP) and Sacrificial Anodes.

- Impressed Current Anti-Fouling (ICAF)

- Marine Growth Prevention System (MGPS)

- Boarding Equipment – ISO 5488 accommodation ladders and marine-grade aluminium gangways.

ICCP and sacrificial anode solutions are tailored to specific vessel and structure profiles, ensuring optimal corrosion control under varying operating conditions. ICAF/MGPS systems reduce biofouling in seawater circuits, improving efficiency and minimizing maintenance downtime. Harbinger boarding equipment, including ISO 5488 accommodation ladders and marine-grade aluminum gangways, is designed to provide safe, reliable access with minimal maintenance and long service life.

Separator Spares & Equipment is your trusted long-term partner for MME Group systems and solutions. We support the full lifecycle of MME Group equipment, from specification and supply to spare parts and technical support, helping operators achieve safe, reliable, and cost-effective operation while protecting critical marine and offshore assets.

MME Group

Marine Growth Prevention and Corrosion Solutions

Cathodic Protection

Corrosion remains one of the most significant threats to the long-term integrity, safety, and profitability of marine and coastal assets. It is estimated that nearly 4% of global GDP is lost each year due to corrosion-related damage and mitigation. Ships, offshore platforms, offshore wind turbines, port and harbor infrastructure, flood barriers, and other submerged or splash-zone structures require robust corrosion protection strategies to ensure reliable performance throughout their service life. For this reason, corrosion control should be a core consideration during the planning, engineering, construction, and operational phases of any asset.

Corrosion remains one of the most significant threats to the long-term integrity, safety, and profitability of marine and coastal assets. It is estimated that nearly 4% of global GDP is lost each year due to corrosion-related damage and mitigation. Ships, offshore platforms, offshore wind turbines, port and harbor infrastructure, flood barriers, and other submerged or splash-zone structures require robust corrosion protection strategies to ensure reliable performance throughout their service life. For this reason, corrosion control should be a core consideration during the planning, engineering, construction, and operational phases of any asset.

Failure to implement effective corrosion protection can lead to escalating maintenance costs, reduced operational availability, and diminished return on investment. In severe cases, structural degradation can create serious safety hazards, including environmental incidents and risks to personnel, ultimately impacting both operational continuity and organizational reputation.

With decades of field-proven expertise, MME Group specializes in the design and application of sacrificial anode systems and impressed current cathodic protection (ICCP) solutions. Their technologies are engineered to safeguard vessels and marine structures against corrosion, extending asset life, reducing lifecycle costs, and supporting safe, reliable operations in demanding environments.

MME Group Authorized Distributor: Marine Corrosion & Cathodic Protection

Separator Spares & Equipment provides MME Group’s cathodic protection systems, including sacrificial anodes, Impressed Current Cathodic Protection (ICCP), shaft grounding systems, and monitoring systems.

Impressed Current Anti-Fouling (ICAF/MGPS)

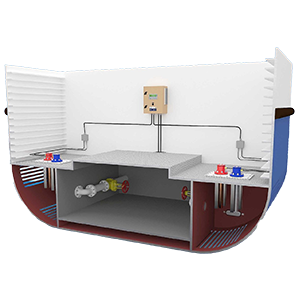

Marine fouling in seawater cooling systems poses a significant risk to the performance and reliability of vessels and offshore installations. Biofouling restricts flow, reduces heat transfer efficiency, accelerates corrosion, and increases fuel consumption. Mechanical cleaning and removal of marine growth from seawater piping and sea chests can be costly, labor-intensive, and often result in unplanned downtime. To mitigate these risks, MME Group developed the Marine Growth Prevention System (MGPS), also known as Impressed Current Anti-Fouling (ICAF), to provide continuous, proactive protection.

Marine fouling in seawater cooling systems poses a significant risk to the performance and reliability of vessels and offshore installations. Biofouling restricts flow, reduces heat transfer efficiency, accelerates corrosion, and increases fuel consumption. Mechanical cleaning and removal of marine growth from seawater piping and sea chests can be costly, labor-intensive, and often result in unplanned downtime. To mitigate these risks, MME Group developed the Marine Growth Prevention System (MGPS), also known as Impressed Current Anti-Fouling (ICAF), to provide continuous, proactive protection.

Marine Growth Prevention Systems (MGPS) or Impressed Current Anti-Fouling (ICAF) systems use copper anodes and a compact control unit that precisely regulates current output. When energized, the system releases controlled levels of copper ions into the seawater flowing through piping, sea chests, and cooling circuits. This creates an environment that inhibits the settlement and growth of marine organisms such as barnacles, mussels, and algae, thereby helping maintain optimal flow conditions, improve thermal efficiency, and reduce maintenance requirements over the asset’s life.

Marine Growth Prevention Systems (MGPS) or Impressed Current Anti-Fouling (ICAF) systems use copper anodes and a compact control unit that precisely regulates current output. When energized, the system releases controlled levels of copper ions into the seawater flowing through piping, sea chests, and cooling circuits. This creates an environment that inhibits the settlement and growth of marine organisms such as barnacles, mussels, and algae, thereby helping maintain optimal flow conditions, improve thermal efficiency, and reduce maintenance requirements over the asset’s life.

Impressed Current Cathodic Protection (ICCP)

Sacrificial anodes provide a simple, passive form of cathodic protection, but they cannot automatically adapt to changing conditions such as coating damage, altered operating profiles, or variations in seawater chemistry. In addition, anode mass is designed for a defined service life, meaning periodic inspection and replacement are required to maintain adequate cathodic protection levels.

Sacrificial anodes provide a simple, passive form of cathodic protection, but they cannot automatically adapt to changing conditions such as coating damage, altered operating profiles, or variations in seawater chemistry. In addition, anode mass is designed for a defined service life, meaning periodic inspection and replacement are required to maintain adequate cathodic protection levels.

Impressed Current Cathodic Protection (ICCP) systems offer a more controlled and responsive solution. These systems incorporate one or more reference electrodes and multiple ICCP anodes connected to a dedicated power supply. The reference electrodes continuously measure the electrochemical protection potential of the submerged structure, and the control unit automatically adjusts current output to maintain optimal protection. By delivering precisely regulated current, ICCP systems effectively suppress the corrosion process while enabling real-time monitoring and performance verification.

With proper design, installation, operation, and maintenance, ICCP systems can provide reliable corrosion protection for 25 years or more. With the support of the MME Group, Separator Spares & Equipment can configure systems using proven standard components or engineer fully customized solutions tailored to the specific requirements of vessels, offshore assets, and marine infrastructure.

Harbinger Boarding Equipment - Accommodation Ladders (ISO 5488) and Gangways

Harbinger Boarding Equipment from MME Group is engineered to provide safe, reliable transfer of crew and passengers between vessels, offshore installations, and shore facilities in a wide range of operating conditions. Manufactured from marine-grade, seawater-resistant aluminum, Harbinger boarding systems are designed to deliver long service life with minimal maintenance while meeting the stringent safety and performance requirements of commercial marine, offshore, and naval applications. The product range includes accommodation ladders, gangways, and associated access solutions, all developed with a focus on operational safety, durability, and compliance.

Harbinger Accommodation Ladders (ISO 5488)

Harbinger accommodation ladders are designed and manufactured in accordance with ISO 5488 and are suitable for most vessel types. These fixed, curved-step ladders feature extruded, anti-slip treads and solid yet lightweight stringers, providing a secure walking surface and ease of handling. With inclination angles typically ranging from 0 to 55 degrees, Harbinger accommodation ladders can be configured to suit varying freeboards and operating profiles. Optional features such as turntable top platforms, wire guides, winches, and self-stowing arrangements allow seamless integration with existing vessel structures while ensuring safe deployment and retrieval.

Harbinger Gangways

Harbinger gangways are engineered to bridge gaps ranging from short ship-to-shore transfers to long-span offshore connections. Available in standard configurations or as fully bespoke solutions, these lightweight aluminum gangways are designed to accommodate shallow or steep angles while maintaining stability and user safety. Anti-slip walking surfaces, self-locking stanchions, and a comprehensive range of accessories enable customization for specific site conditions and regulatory requirements.

Together, Harbinger accommodation ladders and gangways provide a complete boarding solution focused on safety, reliability, and long-term asset performance.

Sacrificial Anodes

MME Group has decades of experience applying sacrificial anodes to salt, brackish, and fresh water in various sizes. Maritime structures, primarily constructed from steel, are highly vulnerable to corrosion because seawater acts as an electrolyte. To prevent this process of gradual material loss, sacrificial anodes made of more active metals such as zinc, aluminum, or magnesium are used. These anodes, attached to the steel structure, oxidize more easily, turning the structure itself into a cathode and protecting it from corrosion. All MME Group’s zinc and aluminium anodes are produced in their fully owned ISO 9001 certified foundry located in Faversham, UK.

MME Group has decades of experience applying sacrificial anodes to salt, brackish, and fresh water in various sizes. Maritime structures, primarily constructed from steel, are highly vulnerable to corrosion because seawater acts as an electrolyte. To prevent this process of gradual material loss, sacrificial anodes made of more active metals such as zinc, aluminum, or magnesium are used. These anodes, attached to the steel structure, oxidize more easily, turning the structure itself into a cathode and protecting it from corrosion. All MME Group’s zinc and aluminium anodes are produced in their fully owned ISO 9001 certified foundry located in Faversham, UK.

In saltwater, both zinc anodes and aluminium anodes are suitable, but aluminium has a better reactivation performance. In brackish water, aluminium anodes are recommended. In pure freshwater, magnesium anodes are the best-performing anode material. In polluted water or when a boat is temporarily in brackish water, aluminum anodes are the preferred choice.

Separator Spares & Equipment provides zinc anodes, aluminum anodes, and magnesium anodes.

Brief History of MME Group

1963 Materiaal Metingen NV was founded.

1990 Materiaal Metingen Europe BV was established to further develop specialised corrosion prevention and inspection services and products for the maritime industry.

2016 Separator Spares & Equipment, LLC signed a distributor agreement with the MME Group, providing Group Impressed Current Systems, Antifouling Systems, Sacrificial Anodes (Aluminum Anodes, Zinc Anodes), and Harbinger Boarding Equipment.