redFox Environmental

Separator Spares & Equipment, LLC is an Authorized redFox Environmental Services Distributor and Service Center for the Gulf Coast region. Since 1970, redFox has been building reliable sewage treatment systems for marine, offshore, and land applications.

redFox Environmental Services

Based in Louisiana, redFox Environmental Services is the leading manufacturer of reliable wastewater treatment systems. Back in the mid 1970’s, redFox was the original pioneer in the development of packaged sewage treatment systems and was instrumental in shaping the MSD federal regulations for the USCG. With over 6,000 installations, redFox Environmental is a worldwide leader in self-contained wastewater treatment units. Their systems are used worldwide, meet strict environmental standards, and are available in various sizes. All units are USCG- and IMO-certified and EPA-compliant.

Designed for reliability, compliance, and long-term performance, RedFox Environmental Services solutions support complete onboard and facility-based wastewater management systems. RedFox Environmental products are used in a wide range of demanding applications, such as:

- Sewage Treatment Units – USCG Type II MSD Certification and IMO Resolution MEPC.227(64) Certified.

- Vacuum Collection, Holding, and Transfer (VCHT) Systems – Integrated or standalone.

- Compactors

- Low-Volume Flush Toilets

- Macerators and Grinder Units – transport and reduce the particle size of solids in wastewater flows.

- Spare Parts and Consumables – Range of janitorial, consumables, and cleaning products.

Engineered to meet the most demanding marine and offshore sanitation standards, redFox systems deliver reliable, proven solutions for marine sewage treatment and wastewater management across commercial vessels, offshore platforms, and industrial applications. RedFox Environmental products are designed to operate consistently in harsh environments, providing effective biological treatment while meeting stringent USCG, IMO, and MARPOL Annex IV discharge requirements.

RedFox Environmental offers a comprehensive range of engineered solutions, including certified marine sanitation devices (MSDs), sewage treatment plants (STPs), vacuum collection systems (VCHT), grinders, and waste-handling equipment. Each system can be designed to match vessel size, crew capacity, and operational demands, ensuring regulatory compliance, operational efficiency, and long-term durability. Contact us today to learn how redFox Environmental Services can help you achieve dependable wastewater treatment performance, long-term reliability, and environmental compliance across your maritime fleet.

redFox Environmental

Wastewater Treatment Units

Offshore Platform Sewage Treatment

Vacuum / VCHT

Compactors

Macerators / Grinders

Toilets

Consumables

redFox Marine Sewage Treatment Systems - Metal

The Marine Series – Metal from redFox Environmental Services is engineered to deliver superior sewage treatment performance, even in the most demanding marine environments. The redFox Marine series clarifier operates under fluid head pressure, allowing flocculation and settling of solids in the clarification chamber to occur consistently while the vessel is in motion. The clarifier chamber is fully enclosed and positioned lower than the waterline in the aeration chamber, ensuring effective solids separation and high-quality discharge.

The Marine Series – Metal from redFox Environmental Services is engineered to deliver superior sewage treatment performance, even in the most demanding marine environments. The redFox Marine series clarifier operates under fluid head pressure, allowing flocculation and settling of solids in the clarification chamber to occur consistently while the vessel is in motion. The clarifier chamber is fully enclosed and positioned lower than the waterline in the aeration chamber, ensuring effective solids separation and high-quality discharge.

This design provides superior discharge water quality compared to competitors’ open-style clarifiers, which are vulnerable to vibration and rolling seas. Open clarifiers can fail to properly settle solids, resulting in reduced discharge quality. The redFox Marine Series maintains consistent separation performance under motion, providing operators with dependable wastewater treatment even in harsh offshore conditions.

The Marine Series – Metal is available in capacities ranging from 100–15,000 GPD and is designed for 2–750 persons, making it suitable for a wide range of marine vessels and offshore platforms. These USCG-certified sewage treatment systems are offered in standard configurations or can be customized to meet specific space limitations and operational requirements. Maintenance requirements are minimal due to the very few moving parts, and no special tools are needed for service or repairs. The system also offers low power and utility consumption, produces no odor, and operates efficiently with both fresh and saltwater. Disinfection is achieved using common household bleach, providing a practical and cost-effective solution for ongoing operation.

The redFox Marine Series units are Bureau Veritas certified to meet IMO Resolution MEPC.227(64), the standard that applies to all sewage treatment systems installed after January 1, 2016. The redFox Environmental Marine Series is designed, manufactured, tested, and certified to meet or exceed MEPC.227(64) effluent standards, providing operators with confidence in regulatory compliance and reliable performance.

redFox Marine Sewage Treatment Systems - Fiberglass

The Marine Series – Fiberglass from redFox Environmental Services is engineered to deliver high-quality sewage treatment performance with a compact, corrosion-resistant design. The redFox Marine series clarifier operates under head pressure, ensuring proper separation and solids settling and resulting in consistently clean discharge water quality. Unlike competitors that use open-style clarifiers, the redFox Marine Series avoids issues caused by movement and vessel motion, ensuring solids settle properly and maintaining optimal discharge quality even in rough marine conditions.

The Marine Series – Fiberglass from redFox Environmental Services is engineered to deliver high-quality sewage treatment performance with a compact, corrosion-resistant design. The redFox Marine series clarifier operates under head pressure, ensuring proper separation and solids settling and resulting in consistently clean discharge water quality. Unlike competitors that use open-style clarifiers, the redFox Marine Series avoids issues caused by movement and vessel motion, ensuring solids settle properly and maintaining optimal discharge quality even in rough marine conditions.

The redFox Marine Series is available in capacities ranging from 200–2,000 GPD and is designed for 4–100 persons, making it suitable for a wide range of maritime vessels and offshore platforms. Maintenance requirements are minimal due to very few moving parts, and no special tools are required if maintenance or repairs are ever needed. The system is also designed for low power and utility consumption, produces no odor, and operates efficiently using either fresh or saltwater. Disinfection is achieved using common household bleach, offering a practical and cost-effective solution for ongoing operation.

The redFox Marine Series units are Bureau Veritas certified to meet IMO Resolution MEPC.227(64), the standard that applies to all sewage treatment systems installed after January 1, 2016. The redFox Environmental Marine Series is designed, manufactured, tested, and certified to meet or exceed IMO MEPC.227(64) effluent standards, providing operators with confidence in regulatory compliance and reliable performance.

redFox FoxPac Sewage Treatment Systems

The redFox FoxPac sewage treatment system series is engineered specifically for motor vessels that have limited space and weight capacity for a sewage processing system. Designed to be smaller than redFox’s standard marine units, the FoxPac series offers a compact yet reliable wastewater treatment solution that meets USCG Type II MSD requirements. This wastewater treatment technology has been utilized by redFox for over 40 years, demonstrating proven performance and long-term reliability.

The redFox FoxPac sewage treatment system series is engineered specifically for motor vessels that have limited space and weight capacity for a sewage processing system. Designed to be smaller than redFox’s standard marine units, the FoxPac series offers a compact yet reliable wastewater treatment solution that meets USCG Type II MSD requirements. This wastewater treatment technology has been utilized by redFox for over 40 years, demonstrating proven performance and long-term reliability.

To create the scaled-down FoxPac version, retention time was reduced, and the gravity separation process was combined with a high-rate biological aerobic filtration system across two treatment tanks. This design ensures effective treatment within a compact footprint while maintaining compliance with stringent marine sanitation standards. The FoxPac series is available in capacities ranging from 50–2,500 GPD, with the fiberglass models offering capacities of 50–350 GPD. It supports 1–125 persons, with fiberglass versions designed for 1–18 persons, and units can be customized to meet specific space limitations and vessel requirements.

The FoxPac system delivers low power and utility consumption while maintaining high performance, and it produces no odor, ensuring a clean onboard environment. Maintenance is minimal due to a few moving parts and no special tools required, keeping operational costs low. The system operates effectively with both fresh and saltwater and uses common household bleach for disinfection, making it practical and cost-effective for ongoing operation.

The redFox Environmental FoxPac Fiberglass series is ideally suited for small-vessel applications in the marine and pleasure-craft industries. It follows the same proven process as the original FoxPac system, using gravity separation combined with biological aerobic filtration, but is fabricated from fiberglass instead of metal, providing a lighter, corrosion-resistant option without sacrificing treatment performance.

redFox Conventional Sewage Treatment Systems

The Conventional Series Sewage Unit from redFox Environmental Services is specifically designed for fixed offshore platforms and land-based installations, offering a reliable wastewater treatment solution for demanding industrial environments. Using the extended aeration process, the sewage treatment unit is portable, easy to install, and simple to operate. The structure and components are engineered for a 20-year service life, even under the harshest conditions, and some of the first units ever built by redFox remain in operation today, demonstrating the design’s durability and longevity.

The Conventional Series Sewage Unit from redFox Environmental Services is specifically designed for fixed offshore platforms and land-based installations, offering a reliable wastewater treatment solution for demanding industrial environments. Using the extended aeration process, the sewage treatment unit is portable, easy to install, and simple to operate. The structure and components are engineered for a 20-year service life, even under the harshest conditions, and some of the first units ever built by redFox remain in operation today, demonstrating the design’s durability and longevity.

The Conventional Series uses a three-chamber process to effectively treat wastewater. The aeration chamber supports naturally occurring bacteria that break down waste, the clarification chamber separates bacteria sludge from treated water, and the disinfection chamber eliminates any remaining living bacteria before discharge into the environment. This process ensures a consistent and high-quality effluent while maintaining operational simplicity.

The Conventional Series is available in capacities ranging from 100–20,000 GPD and is designed for 2–666 persons, making it suitable for platforms of all sizes. These USCG-certified sewage treatment systems are offered in standard configurations or can be customized to meet specific space limitations and operational requirements. Maintenance is minimal due to the very few moving parts, and no special tools are required for service or repairs. The unit is designed for low power and utility consumption, produces no odor, and operates efficiently with both fresh and saltwater. Disinfection is achieved using common household bleach, offering a practical and cost-effective solution for ongoing operation.

The redFox Environmental Conventional Series is ideal for fixed and temporary facilities, fixed offshore inshore platforms, and remote locations where reliable wastewater treatment is essential.

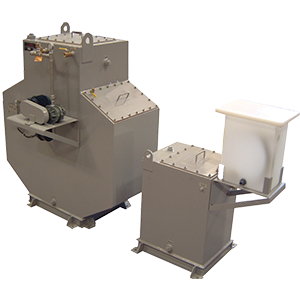

Cajun Crusher Compactors

The redFox Cajun Crusher Compactors are specifically engineered to meet the rigorous demands of the marine industry, where equipment must perform reliably under harsh, challenging conditions. Built with the same high-performance standards and dependability expected of all redFox products, the redFox Cajun Crusher line is designed for trouble-free service, continuous operation, and straightforward routine maintenance. With an estimated life expectancy of 15 years, the redFox Cajun Crusher delivers long-term economic value through durable performance and reduced lifecycle costs.

The redFox Cajun Crusher Compactors are specifically engineered to meet the rigorous demands of the marine industry, where equipment must perform reliably under harsh, challenging conditions. Built with the same high-performance standards and dependability expected of all redFox products, the redFox Cajun Crusher line is designed for trouble-free service, continuous operation, and straightforward routine maintenance. With an estimated life expectancy of 15 years, the redFox Cajun Crusher delivers long-term economic value through durable performance and reduced lifecycle costs.

The redFox Cajun Crusher is intentionally simple and user-friendly. The controls are easily accessible within a closable panel, allowing operators to operate from a single station without extensive training. This ease of use makes the unit practical for busy marine environments where efficiency and simplicity are essential.

Safety is a top priority in the design of the redFox Environmental Cajun Crusher Compactor product line. All models are structurally fabricated to withstand heavy loads and constant use without failure, and all wiring harnesses and electrical, pneumatic, and hydraulic components are routed to maximize personnel safety while ensuring efficient performance. Controls are housed in explosion-proof protectors where needed, and the majority of units are air-operated using proven techniques that deliver reliable, foolproof operation.

Low-Volume Flush Toilets

Low-Volume Flush Toilets from redFox Environmental Services provide a compact, efficient sanitation solution for marine vessels with limited space. The redFox marine toilet is a self-contained unit designed specifically for tight spaces where conventional toilets cannot fit. Its compact design makes it ideal for small cabins, crew quarters, and compact marine installations where efficient use of space is essential.

Low-Volume Flush Toilets from redFox Environmental Services provide a compact, efficient sanitation solution for marine vessels with limited space. The redFox marine toilet is a self-contained unit designed specifically for tight spaces where conventional toilets cannot fit. Its compact design makes it ideal for small cabins, crew quarters, and compact marine installations where efficient use of space is essential.

This modern, self-contained toilet is highly water-efficient, using just one (1) gallon per flush, making it suitable for operators seeking water conservation and environmentally responsible sanitation solutions. The design also accommodates users with limited mobility by providing easier access and functionality in a compact footprint. The redFox low-volume flush toilets are designed for practical marine use without compromising comfort or performance.

The toilet dimensions are 15 3/4″ H x 14 1/2″ W x 18 1/4″ D, and it operates on 110–115V, 60Hz electrical supply, with a maximum amperage of 7.2 amps (0.3 HP). The discharge pump can move wastewater vertically up to 9 feet (3 meters) and horizontally up to 100 feet (33 meters), ensuring reliable operation in a variety of marine plumbing configurations.

Macerators and Grinder Units

Macerator & Grinder Units from redFox Environmental Services are engineered to transport wastewater and reduce the particle size of solids in the flow, ensuring effective handling and compliance with discharge regulations. These units are commonly used to lift wastewater to the inlet of redFox sewage treatment systems or to reduce the size of solid particulates prior to discharge.

redFox Grinder Tanks

RedFox Grinder Tanks include a pump, a tank, and a control panel. A cutting mechanism macerates waste and grinds sewage, while the pump is controlled by a level float sensor and operates on demand for efficient, automated performance.

The redFox grinder units are designed for reliable operation and ease of use. Typical features include a control panel for simplex pump operation with hand/off/auto (H/O/A) level control, skid mounting with lifting lugs, and options for external or internal pump mounting. The system can be designed with a submersible sewage handling pump in simplex or duplex arrangements, and the macerator grinds solids to 1/4″ or smaller, ensuring compliance with offshore discharge requirements.

redFox waterFox Macerator Units

The redFox waterFox macerator is specifically designed for offshore platforms that do not require a sewage treatment unit but must comply with regulations limiting solid waste size to 1/4″ or less. It operates using high-pressure water from the platform fire pump or another source to hydraulically break solids apart. The redFox Environmental waterFox unit connects inline to the existing sewage line and requires no electricity or moving parts, making it a low-maintenance solution. Its robust design includes single-frame construction, Schedule 80 piping, oversized black plates, and patent nozzles, and it is intended for continuous seawater feed supplied by the platform.

The redFox waterFox macerator is specifically designed for offshore platforms that do not require a sewage treatment unit but must comply with regulations limiting solid waste size to 1/4″ or less. It operates using high-pressure water from the platform fire pump or another source to hydraulically break solids apart. The redFox Environmental waterFox unit connects inline to the existing sewage line and requires no electricity or moving parts, making it a low-maintenance solution. Its robust design includes single-frame construction, Schedule 80 piping, oversized black plates, and patent nozzles, and it is intended for continuous seawater feed supplied by the platform.

Vacuum Collection, Holding, and Transfer (VCHT) Systems

The redFox marine vacuum sewage systems, also known as Vacuum Collection Holding Tank (VCHT) systems, are engineered to provide reliable, low-maintenance wastewater collection for commercial vessels, offshore platforms, and marine installations. Built using proven vacuum technology and high-quality components, these systems are designed to perform consistently in harsh marine operating environments.

The redFox marine vacuum sewage systems, also known as Vacuum Collection Holding Tank (VCHT) systems, are engineered to provide reliable, low-maintenance wastewater collection for commercial vessels, offshore platforms, and marine installations. Built using proven vacuum technology and high-quality components, these systems are designed to perform consistently in harsh marine operating environments.

As a critical component of modern marine sanitation devices (MSD), redFox VCHT systems are operator-friendly, highly efficient, and adaptable to a wide range of vessel configurations. Their flexible design allows for multiple system variations to meet space, piping, and regulatory requirements.

Integrated or Standalone Marine Vacuum Sewage Systems

The redFox VCHT systems may be installed as standalone marine vacuum sewage systems or fully integrated into the vessel’s sewage treatment plant. When integrated with an approved marine sewage treatment system, overall system performance is enhanced and, in many cases, allows for a smaller sewage treatment system footprint, reducing space, weight, and installation cost.

RedFox Environmental’s engineering team specializes in custom VCHT tank design, providing solutions that fit your vessel’s layout, operational profile, and available space, without compromising performance or compliance.

Standard Benefits of redFox VCHT Marine Vacuum Systems:

– High-velocity vacuum discharge reduces the risk of line clogging and solids accumulation

– Small-diameter collection piping (1¼″ to 4″) lowers system weight and simplifies installation

– Vertical lift capability allows wastewater transport over elevation changes and long pipe runs

– Reduced water consumption, ideal for vessels with limited freshwater supply

– Proven marine vacuum technology widely used in commercial, offshore, and industrial marine applications

– Compatible with IMO and USCG-approved marine sanitation devices

Brief History of redFox Environmental

1970 Red Fox Industries established.

1990 RedFox Environmental Services was formally incorporated.

2013 Separator Spares & Equipment, LLC becomes the designated US Gulf Coast Sales Distributor.