H2O miniBOSS Oily Water Separator

Separator Spares & Equipment, LLC is an Authorized Service Center and Distributor for H2O miniBOSS Oily Water Separators. In 2021, H2O, LLC acquired the assets of BOSS Separators, oily water separators designed for the maritime industry. H2O manufactures a complete line of oily water separators, marine sanitation devices, and reverse osmosis desalination systems.

miniBOSS Separator

The H2O miniBOSS oily water separator (OWS) is a marine bilge treatment system specifically engineered to meet the stringent international standards set by IMO Resolution MEPC.107(49). All BOSS oily water separators are IMO MEPC.107(49) certified and have USCG, ABS, BV, and MED Certificates of Approval.

miniBOSS Separator Design

The H2O miniBOSS oily water separator is a USCG 107(49) certified alternative to a full-blown oily water separator. The H2O miniBOSS separator does not attempt to separate the oil; it adsorbs it through a series of filters. The key is in the filters. The first filter is a sediment filter. These are inexpensive and available everywhere. In reality, this sediment filter and the solids remove a lot of oil. This sediment filter is followed by two (2) BOSS oil removal filters.

These cartridges are the key to the H2O miniBOSS oily water separator performance and are the only approved cartridges that comply with the 107(49) regulations. The BOSS oil removal filters do a great job of removing all the oil right up to their capacity.

The H2O miniBOSS oily water separator is designed for low volume (2 GPM (0.45 m3/hr)) applications as an affordable solution to the bilge water disposal problem. The H2O miniBOSS has an IMO MEPC 107(49) certified oil content monitor. This is the same monitor that other marine oil-water separators use and has all the features, including the ability to track 18 months’ worth of data. Also included are a process pump and a 3-way diversion valve, just like a full-blown separator.

The H2O miniBOSS oily water separator is mounted on a wall and takes up very little space. The H2O miniBOSS is perfect for smaller vessels that need certification but have a low bilge volume.

miniBOSS Oily Water Separator

IMO 107(49) Certified Oil Water Bilge Filter

Features & Advantages

– Low capital cost

– Simple to install and operate

– Low maintenance

– Small footprint (wall-mounted)

– IMO MEPC.107(49) certified oil content monitor

– Flow Rate: 0.45 m3/hr (2 GPM)

– Electric diaphragm displacement process pump

– Fine solids and oil removed by simple filtration

– Dimensions: 34″ W x 40″ H x 10″ D

How does the H2O miniBOSS oily water separator work?

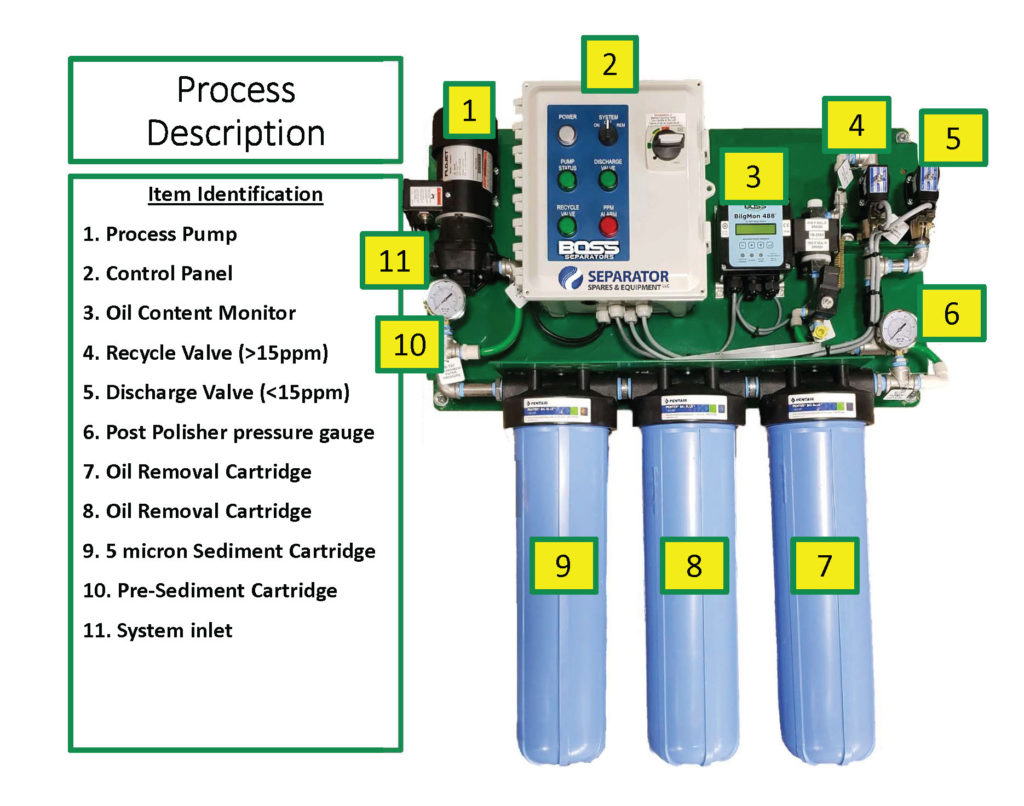

The H2O miniBOSS oily water separator draws in bilge water using the diaphragm pump (#1) through the system inlet (#11). The pump is fitted with a #20 mesh screen to help prevent damage to the pump. The pump then pushes the bilge water to the first of three cartridges.

The H2O miniBOSS oily water separator draws in bilge water using the diaphragm pump (#1) through the system inlet (#11). The pump is fitted with a #20 mesh screen to help prevent damage to the pump. The pump then pushes the bilge water to the first of three cartridges.

The first cartridge (#9) is a sediment cartridge; the second (#8) and third (#7) are oil removal cartridges. The pre-sediment pressure gauge (#10) and the post-polisher pressure gauge (#6) will help you determine when to change the sediment (#9) cartridge.

Once the bilge water has passed through the polishing cartridges, the Oil Content Monitor (#3) continuously samples the water and determines whether the oil content is above or below the 15 PPM limit. If it is greater than 15 PPM, the Recycle valve (#4) will open and return the rejected water to the bilge. If the sample is less than 15 PPM, the discharge valve (#5) will open and discharge it overboard.

The polishing cartridges will hold about 10oz of oil each. The sediment cartridge will also aid in removing oil droplets larger than 5 microns. The amount of oil in your bilge will ultimately determine how long each cartridge will last. You will most likely need to replace the sediment cartridge more frequently than the polishing cartridges. The polishing cartridges are replaced at the same time when the Oil Content Monitor (OCM) no longer reaches less than 15 PPM.

Need miniBOSS oily water separator parts?

Separator Spares & Equipment, LLC specializes in spare parts, consumables, equipment, and services for H2O BOSS oil water separators and oil content monitors.

Separator Spares & Equipment, LLC specializes in spare parts, consumables, equipment, and services for H2O BOSS oil water separators and oil content monitors.

BOSS oily water separators are designed to separate oil and water mixtures (bilge water) into separate components before discharging from the vessel. We are committed to keeping your current oil-water separator environmentally compliant with USCG and IMO requirements. We are your link to IMO MEPC 107(49) compliance.

To learn more about oil water separator spare parts, visit our Oily Water Separator Spare Parts webpage.

Need your H2O miniBOSS oily water separator serviced?

Separator Spares & Equipment, LLC offers a full range of services for BOSS oily water separators and oil content monitors. We are committed to keeping your current H2O miniBOSS oily water separator environmentally compliant with US Coast Guard and IMO MEPC 107(49) requirements. We can provide scheduled maintenance services to assist the operator in essential maintenance functions.

Separator Spares & Equipment, LLC offers a full range of services for BOSS oily water separators and oil content monitors. We are committed to keeping your current H2O miniBOSS oily water separator environmentally compliant with US Coast Guard and IMO MEPC 107(49) requirements. We can provide scheduled maintenance services to assist the operator in essential maintenance functions.

With our experience in oily water separators, Separator Spares & Equipment can provide the following services:

– H2O BOSS Factory-Trained Service Technicians

– Annual inspection, maintenance, repair, and service your BOSS Separators

– Oil content monitor calibration verification

– On-site training for vessel/crew personnel

– Genuine H2O BOSS spare parts

– Replacement oil content monitors

– New IMO MEPC 107(49) certified oily water separators

To learn more, visit our Oil Water Separator Service and Solutions webpage.