Facet Filtration

Separator Spares & Equipment, LLC is an Authorized Kaydon Filtration and Facet Filtration Distributor. Facet Filtration is a global leader in cutting-edge oil filtration technologies. Facet products are trusted in industries such as aviation (aviation fuel filtration solutions), maritime, oil & gas, power generation, petrochemical, military/defense, where equipment reliability and uptime are essential.

Facet Filtration

Facet Filtration is a global leader in advanced filtration and separation for fuels, oils, and process fluids. With decades of filtration experience, Facet Filtration has been dedicated to protecting critical systems by ensuring the cleanliness and reliability of fluids. From aviation fuel filtration solutions to industrial process streams, Facet designs innovative filtration technologies that prevent contamination, extend equipment life, and minimize downtime. When you need trusted fluid filtration and separation, Facet Filtration is the answer.

Facet Filtration products, including particulate filters, coalescer separator systems, microfilters, filter cartridges, and customized filtration housings, are used in a wide range of demanding applications, such as:

- Coalescer Separators – Remove water and solid contaminants from fuels and process fluids.

- Fuel Filtration Systems – Deliver clean fuel to protect engines, turbines, and power generation equipment.

- JP-5 Fuel Treatment Systems – Ensure jet fuel meets strict military and defense specifications.

- Lube Oil Conditioners – Maintain lubricant cleanliness to extend equipment life and reduce downtime.

- Oily Bilge Water Separators – Achieve MEPC.107(49) compliance.

- Portable Fuel Filtration – Provide on-site, flexible filtration for fuel transfer and storage operations.

- Sewage Treatment Plants – Systems that meet international wastewater discharge standards.

- Turbo-Generator Fuel/Oil Modules – Deliver clean, conditioned fuel to turbo-generators on any vessel.

Engineered to meet the most rigorous industry standards, Facet Filtration solutions deliver consistent performance, fluid cleanliness, and regulatory compliance. By reducing waste, extending fluid life, and enhancing system efficiency, Facet Filtration enables operators to lower the total cost of ownership (TCO) while supporting sustainable, environmentally responsible operations.

Facet Filtration systems are designed to help businesses worldwide meet their fluid cleanliness requirements and extend the life of their equipment. Separator Spares & Equipment is your trusted partner for genuine Facet Filtration solutions, products, and expert support to keep your equipment running at peak performance.

Facet Filtration

Marine Filtration & Separation Systems

Coalescer Separators

Facet Filtration coalescer separators are basically a cylindrically shaped pressure vessel designed specifically to remove solid contaminants such as dirt, rust, scale, sand, and metal particles, as well as remove emulsified, free, and entrained water from the liquid stream.

Facet Filtration coalescer separators are basically a cylindrically shaped pressure vessel designed specifically to remove solid contaminants such as dirt, rust, scale, sand, and metal particles, as well as remove emulsified, free, and entrained water from the liquid stream.

Removable access-opening covers are provided to facilitate replacement of the filter elements contained within the main body of the coalescer separator and to permit cleaning the interior of the vessel.

Suitable mounting supports are provided for anchoring the unit. Inlet, outlet, vent, and drain connections are provided on all units. The size, type, and location of the connections are as specified to suit the installation requirements.

How does the Facet Coalescer Separator work?

Stage 1: Coalescing (Coalescer Cartridge)

The fluid enters the housing and flows through a coalescer cartridge. This cartridge traps and holds solids while causing small, free water droplets to combine into larger, heavier drops. These larger drops fall to the bottom of the housing’s sump.

Stage 2: Separating (Separator Cartridge)

The fluid then flows outward through the second-stage separator cartridges. These cartridges remove any remaining water droplets and very fine solids, ensuring only clean, dry liquid passes through.

Filter Housings

Facet’s M Series filter housings use any of Facet’s high-efficiency filter cartridges. A single pass of product through the system removes solids such as rust, dirt, scale, granules, and other particles commonly found in liquid process streams.

Facet’s M Series filter housings use any of Facet’s high-efficiency filter cartridges. A single pass of product through the system removes solids such as rust, dirt, scale, granules, and other particles commonly found in liquid process streams.

Facet M Series filter housings are available in three styles and in several standard sizes to accommodate specific flow and filtration requirements. They are designed with no internal moving parts to provide easy service and reduced maintenance costs. Each housing is manufactured using quality materials and workmanship to give long-lasting, dependable service.

Facet M Series filter housings can be fitted with either multiple single-length cartridges, stacked 1, 2, or 3 high, or their double-length or triple-length equivalents.

Fuel Gard VF-21SB/22SB

The Facet Fuel-Gard VF-21SB and VF-22SB, when configured as a coalescer separator, are economical, compact housings designed to remove water and solids from aviation fuels.

The Facet Fuel-Gard VF-21SB and VF-22SB, when configured as a coalescer separator, are economical, compact housings designed to remove water and solids from aviation fuels.

Both interior and exterior surfaces of the carbon steel body are epoxy-coated to protect against corrosion. This sturdy, single-cartridge housing is easy to maintain and requires only 2″ (51 mm) base clearance for filter cartridge change-out.

Filter Cartridges

The Facet VF-21SB/22SB Series coalescer separator filter cartridges provide long service life and high solids holding capacity with no unloading characteristics. These filter separator cartridges effectively remove water and solids from fuels.

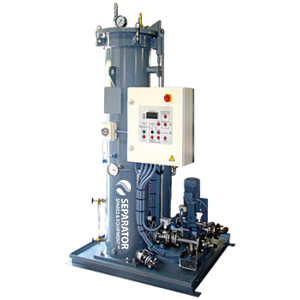

Lube Oil Conditioners

Facet Lube Oil Conditioners are built from carbon steel, epoxy-painted, and designed in accordance with ASME VIII-I. These quality filtration solutions are specially designed to remove solids such as dirt, rust, sand, and metallic wear particles, as well as lube oily water.

Facet Lube Oil Conditioners are built from carbon steel, epoxy-painted, and designed in accordance with ASME VIII-I. These quality filtration solutions are specially designed to remove solids such as dirt, rust, sand, and metallic wear particles, as well as lube oily water.

Trusted Partner for Oil Filtration Systems!

The Facet lube oil conditioners consist of a separator filter, a pumping unit, and a heating unit (optional), all assembled in a skid. The microfilter separator includes coalescer and separator cartridges with a dual objective: retaining the finest particles and removing water, ensuring long life and high effectiveness thanks to their specific properties. Contact us today for quality filtration solutions.

Bilge Water Separators

Whether for military, commercial vessels, or offshore installations, our Facet Bilge Water Separators remove oil, solids, and emulsions from bilge water with precision and reliability. Designed for compact spaces and fully automated operation, they deliver consistent performance to help you meet strict international regulations.

Whether for military, commercial vessels, or offshore installations, our Facet Bilge Water Separators remove oil, solids, and emulsions from bilge water with precision and reliability. Designed for compact spaces and fully automated operation, they deliver consistent performance to help you meet strict international regulations.

The presence of emulsified oil in the bilge water of the latest generation vessels prompted the IMO to issue Resolution MEPC.107(49), which requires that the effluent from bilge water treatment contain surfactant levels below 15 ppm.

A trusted partner and global leader in filtration solutions, Facet bilge water separators provide reliable separation for the harsh marine environments.

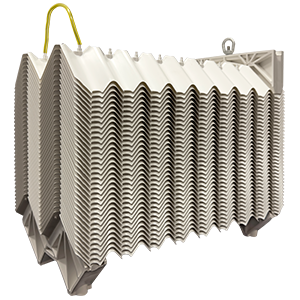

MPak Coalescing Plates

The Facet MPak coalescing plates efficiently separate oil and solids from water in a wide range of demanding environments. Made from a special oleophilic material, these plates encourage oil droplets to merge and rise to the surface, while solids settle below for easy removal.

The Facet MPak coalescing plates efficiently separate oil and solids from water in a wide range of demanding environments. Made from a special oleophilic material, these plates encourage oil droplets to merge and rise to the surface, while solids settle below for easy removal.

The customizable, modular design allows for straightforward installation, retrofitting, and maintenance, ensuring reliable performance with minimal upkeep.

Sewage Treatment Plants

Facet Sewage Treatment Plants for marine applications are designed for the treatment of black (toilets, urinals, and hospital) and grey (sinks, showers, laundry, and galley) water generated on board. The treatment consists of the purification and subsequent disinfection of the water to achieve an effluent whose quality meets the IMO requirements.

Facet Sewage Treatment Plants for marine applications are designed for the treatment of black (toilets, urinals, and hospital) and grey (sinks, showers, laundry, and galley) water generated on board. The treatment consists of the purification and subsequent disinfection of the water to achieve an effluent whose quality meets the IMO requirements.

The purification mechanism is based on a biological process of active sludge with extended aeration: the microorganisms in the biomass purify the water, so that no additional chemical treatment throughout the process is necessary. The plants are built in a single steel module to ease transportation and on-board installation. The module is divided into three chambers (aeration, settling, and discharge/disinfection), each with its respective inspection accesses.

In the aeration chamber are housed the air diffusers, which provide the necessary oxygenation for the microorganisms and generate the agitation that homogenizes the content of the reactor.

The settling chamber, pressurized to improve the process of deposition of solids, contains the biological filter and the sludge recirculation connections and grease toward the aeration chamber.

Facet sewage treatment plants can be provided with a built-in vacuum system (VTP Series) that takes charge of the transportation of black water along the vacuum system to the treatment plant. The vacuum in the circuit is achieved automatically with the ejector and circulating pump.

Turbo-Generator Fuel/Oil Modules

The Facet Turbo-Generator Fuel/Oil Modules leverage the sum of Facet’s know-how in microfiltration and separation, along with their filtration experience in handling fueling systems, providing fully automated pumping, filtration, and conditioning of the fuel supplied to the turbo-generator.

The Facet Turbo-Generator Fuel/Oil Modules leverage the sum of Facet’s know-how in microfiltration and separation, along with their filtration experience in handling fueling systems, providing fully automated pumping, filtration, and conditioning of the fuel supplied to the turbo-generator.

Facet Filtration designs, manufactures, and distributes a wide range of Turbo-Generator Fuel/Oil Modules for the maritime market, tailored to the specific needs of customers and in compliance with the most stringent specifications of regulatory agencies. Facet Filtration is a true trusted partner and global leader in oil filtration solutions. Contact us today for quality filtration solutions.

Brief History of Facet Filtration

1941 Kaydon Engineering Company was founded.

1943 Warner Lewis Company (Facet) established.

1976 After several corporate changes, including acquisitions by Fram and Bendix, Facet was reestablished as Facet Enterprises.

1984 Kaydon Corporation took over the Bowser Turbine Oil Conditioner product line.

2001 Facet qualifies coalescer/separator to MIL-PRF-15618G for US Navy, M Fuel.

2007 CLARCOR acquired Perry Equipment Corp (PECO) and merged them with Facet International.

2013 SKF Group acquired Kaydon Corporation, which included Kaydon Filtration and its sister filtration company, Purafil, Inc.

2015 Kaydon Custom Filtration Corporation (Kaydon Filtration), along with Purafil, was acquired by Filtration Group Corporation, an affiliate of Madison Industries.

2016 Facet is the first filtration company to qualify coalescers to MIL-PRF-52308 for the US Army.

2018 Filtration Group Corporation, an affiliate of Madison Industries, acquired the global Facet filtration business from Parker-Hannifin Corporation.

2021 Kaydon Filtration and Facet Filtration joined forces to provide advanced oil filtration solutions.

2025 Separator Spares & Equipment, LLC signed a distributor agreement with Facet Filtration and Kaydon Filtration.

Certifications

Fuel Oil Certifications

Mil-DTL-5624 NATO F-44 (JP-5, Jet Propellant-5)

Mil-DTL-16884 NATO F-76 Naval Distillate

Mil-DTL-83133 NATO F-34, F-35, F-37 (JP-8, JP-8 w/o FSII, JP8+100)

ASTM D 1655 NATO F-24 JAA

Lube Oil Certifications

Mil-DTL-17331

Mil-DTL-32353

Equipment Environmental Test Requirements

Mil-DTL-901 Shock Test High Impact – Shipboard Machinery

Mil-STD-167 Vibration

Mil-STD-810 Lab and Environmental Testing

Bilge Water Separators

MED

UKCA

USCG

Filter & Filtration Equipment Certifications

ASME

EI 1581

EI 1590

Mil-PRF-52308

Mil-PRF-32148

Mil-PRF-15618

Mil-F-8901E

UFGS 33 52 43.28

STANAG 3967

DEF STAN 49-3

DEF STAN 49-4

Quality Certifications

ISO 9001:2015

PECAL / AQAP 2110