A Simple Guide to Oil Filtration Fluid Contamination

What is the ISO 4406 Cleanliness Code?

To standardize the measurement of particulate contamination in industrial fluids, the International Organization for Standardization (ISO) established the ISO 4406 standard. This code provides a clear and straightforward method for reporting the number of solid contaminant particles present in a fluid sample.

The ISO 4406 Cleanliness Code is a globally recognized standard for quantifying particle contamination in hydraulic and lubrication fluids. By assigning an ISO code to a fluid sample, it provides an accurate picture of the number of particles present within a specific particle size range:≥4 μm, ≥6 μm, and ≥14 μm. This structured reporting method allows engineers and maintenance teams to make data-driven decisions regarding oil filtration efficiency, system health, and preventive maintenance.

Understanding the ISO 4406 Cleanliness Code Format

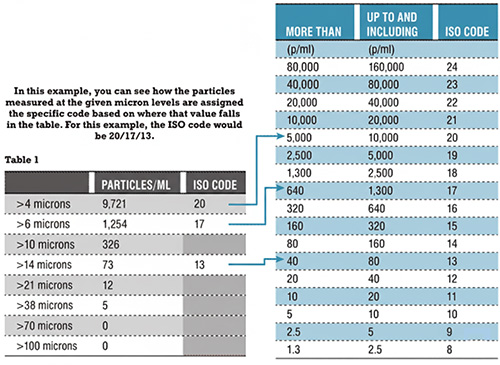

The ISO 4406 cleanliness code is expressed as a series of three (3) numbers, such as 18/16/13. Each individual number corresponds to the quantity of particles of a specific size range per milliliter of the fluid. The three particle size ranges measured are:

The ISO 4406 cleanliness code is expressed as a series of three (3) numbers, such as 18/16/13. Each individual number corresponds to the quantity of particles of a specific size range per milliliter of the fluid. The three particle size ranges measured are:

– First Number: Particles greater than or equal to 4 microns (µ) in size.

– Second Number: Particles greater than or equal to 6 microns (µ) in size.

– Third Number: Particles greater than or equal to 14 microns (µ) in size.

A logarithmic scale determines the ISO 4406 cleanliness code, where each increasing code number represents a doubling of the particle count range. This system allows for a concise representation of a wide range of contamination levels.

To learn more about the ISO cleanliness code, visit Noria’s What is the ISO Cleanliness Code?

Measure. Monitor. Maintain.

Determining Oil Cleanliness Levels

Determining Oil Cleanliness Levels

To protect critical components, facilities establish a target cleanliness level based on equipment sensitivity, operating environment, and industry best practices. Comparing the actual particle count of the industrial fluid to this target oil cleanliness determines whether the system meets its acceptable fluid cleanliness level or requires corrective actions. Maintaining acceptable fluid cleanliness levels within these parameters reduces the risk of abrasive wear, valve sticking, and premature equipment failure.

Importance of Particle Contamination Size Ranges

The range of particles measured under the ISO 4406 cleanliness code is particularly important. Smaller particle sizes can infiltrate sensitive clearances in pumps and valves, while larger particles often indicate more severe contamination or component wear. Tracking both small and large particle counts provides maintenance teams with a comprehensive and accurate picture of fluid health, enabling them to make precise adjustments to filtration and maintenance schedules.

Optimize system health by achieving consistent, measurable oil cleanliness levels!

Proactive Fluid Cleanliness Management

Implementing regular oil analysis based on the ISO 4406 cleanliness code ensures that the cleanliness level remains within your acceptable limits. Continuous monitoring of contaminated particle count trends not only supports achieving and sustaining the target oil cleanliness level but also helps predict potential system issues before failures occur. A proactive approach enhances equipment reliability, minimizes downtime, and prolongs component life.

OIl target cleanliness is not a one-size fits all! It changes based on machine type, downtime length, material, and other factors. You can calculate your target cleanliness with the Noria Oil Target Cleanliness Calculator.

Target ISO Code Cleanliness for Peak Performance!

Separator Spares & Equipment is committed to providing cost-effective oil filtration systems that will positively impact your business. Oil cleanliness and contamination control are an important part of a proactive maintenance strategy. We can assist with oil purification products, solutions, and expertise. We offer a broad range of oil filtration products for industrial fluids designed to remove particles, water, varnish, and other contaminants.

Separator Spares & Equipment is committed to providing cost-effective oil filtration systems that will positively impact your business. Oil cleanliness and contamination control are an important part of a proactive maintenance strategy. We can assist with oil purification products, solutions, and expertise. We offer a broad range of oil filtration products for industrial fluids designed to remove particles, water, varnish, and other contaminants.

Set ISO code targets, and our cost-effective oil filter systems will help you save on maintenance costs (lowering the total cost of ownership), increase reliability, and reduce energy consumption.

Do you need any spare filter parts? Separator Spares & Equipment specializes in genuine and compatible filter spare parts, including elements, housings, and accessories for every application. We are committed to providing reliable filtration solutions that reduce maintenance and minimize downtime.

Oil Purification Systems | Solutions, Service, and Expertise